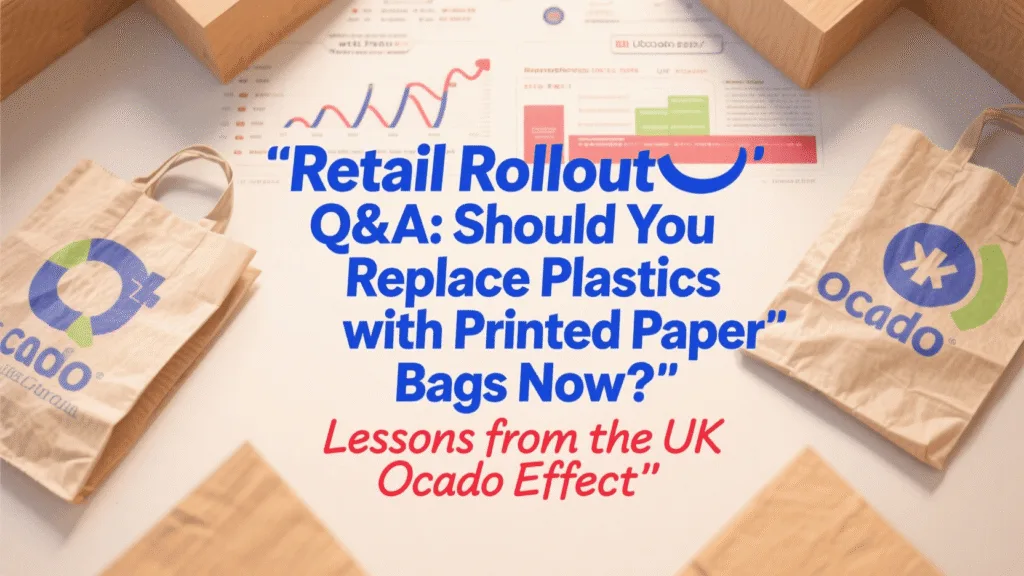

Which Industries Are Driving the Demand for Holographic Paper Bags in 2025–2030?

You’re planning your brand’s future, but the packaging landscape is changing fast. You see eye-catching trends but wonder which ones have the staying power to deliver real ROI…

Read more