Custom Paper Bag manufacturer in China

- Complete Bag Packaging Solutions

Premium customized paper bags that elevate your brand and impress your customers. Sustainable, stylish, and tailored to your exact specifications.

Paper Bag Guide Directory

Explore our comprehensive guide to paper bag customization. Click on any category below to learn more about our offerings and find the perfect solution for your business needs.

Custom Cases

Explore our portfolio of successful custom paper bag projects

MOQ

Minimum order quantities and pricing considerations

Bag Shapes

Various paper bag shapes and styles to choose from

Bag Sizes

Standard and custom sizes for different products

Materials

Paper types, weights, and finishes available

Printing Options

Various printing techniques for your design

Finishing Options

Special finishing techniques to enhance your bags

Handle Options

Different handle types and materials available

Cost Analysis

Understanding the factors that affect pricing

Timeline

Expected production and delivery timeframes

Common Pitfalls

Mistakes to avoid in paper bag customization

Why Us

Our competitive advantages and commitments

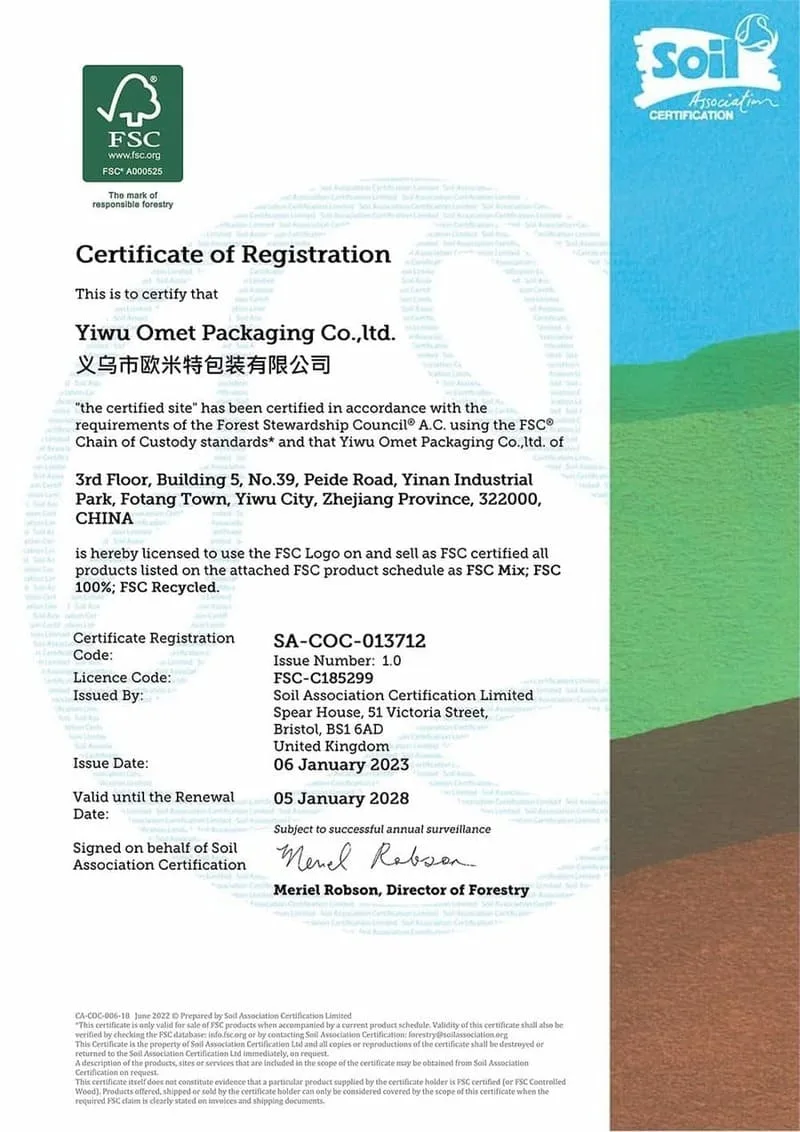

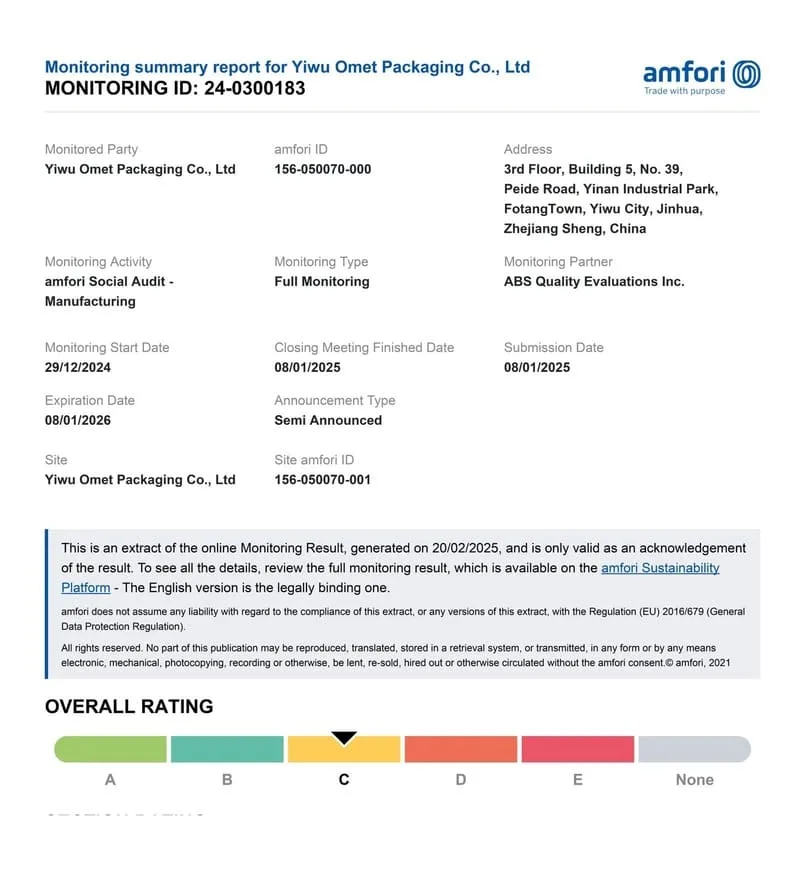

Certifications

Our quality and sustainability certifications

Customer Reviews

What our clients say about our services

FAQ

Answers to frequently asked questions

Related Products

Other packaging solutions we offer

Get Custom Quote

Ready to start your packaging project? Get a personalized quote today.

Custom Paper Bag Solutions

Discover our comprehensive portfolio of custom paper bag manufacturing projects across luxury retail, eco-friendly packaging, cosmetics, jewelry, apparel, and specialty industries worldwide.

Luxury Retail Paper Bags

Premium custom shopping bags featuring gold foil stamping, embossed logos, and satin ribbon handles designed for high-end fashion retailers and luxury boutiques.

Eco-Friendly Kraft Bags

Sustainable white and brown kraft paper bags with recycled paper handles, perfect for organic food brands, farmers markets, and environmentally conscious businesses.

Printed Paper Bags

Vibrant, full-color printed paper bags with special UV coating and matte finishes, designed for contemporary art galleries, museums, and creative merchandise stores.

Premium Cosmetics Bags

Sophisticated black paper bags with embossed logos, spot UV coating, and grosgrain ribbon handles, crafted for premium cosmetics brands and beauty retailers.

Holiday Gift Bags

Festive paper bags with metallic foil stamping, glitter finishes, and holiday-themed prints, perfect for Christmas, New Year, and seasonal celebrations.

Jewelry & Accessories Bags

Small, elegant paper bags with velvet or satin ribbon handles, designed for jewelry shops, watch brands, and accessory boutiques.

Apparel Paper Bags

Fashion-forward bags with full-size printing and reinforced handles, ideal for clothing brands, boutiques, and online apparel retailers.

Wine & Beverage Bags

Tall and durable paper bags with rope handles and reinforced bases, crafted for wine shops, champagne brands, and beverage gift packaging.

Ready to create your custom paper bag solution? Get a personalized quote for your specific industry needs.

Minimum Order Quantity (MOQ) Explained

Learn about minimum order quantity requirements and their impact on pricing strategies.

Quantity Considerations

In the printing industry, quantity is one of the most significant factors affecting price. The higher the quantity, the more cost-effective your order becomes.

Small Orders

MOQ: 500 pcs per design/size

Higher unit cost but lower total investment

Medium Orders

3,000 pcs per design/size

More balanced cost-to-value ratio

Large Orders

5,000+ pcs per design/size

Most competitive pricing available

Additional Considerations

- Different designs or sizes are considered separate orders for MOQ purposes

- Setup costs are amortized across the entire order quantity

- Storage and logistics costs should be factored into larger orders

- Consider your sales cycle and how quickly you'll use the inventory

Paper Bag Shapes: Find Your Perfect Fit

Discover how to select the ideal paper bag shapes that complement your products and enhance your brand identity.

Vertical Bag

Taller than they are wide, perfect for clothing, bottles, and tall items. Elegant and sophisticated appearance.

Horizontal Bag

Wider than they are tall, ideal for books, boxed items, and wider products. Practical and versatile.

Square Bag

Equal width and height, perfect for gift boxes, small items, and creating a balanced look. Modern and clean.

Wide Bottom Bag

Expanded bottom for increased capacity, ideal for bulky items and multiple products. Practical and spacious.

Paper Bag Sizes

Choose the right size for your products to ensure a perfect fit and optimal presentation.

| Size Category | Dimensions (cm) | Ideal For | Common Applications |

|---|---|---|---|

| Small | 11 × 14 × 6 cm | Small accessories, jewelry, cosmetics | Jewelry stores, cosmetic shops, small gifts |

| Medium | 18 × 23 × 10 cm | Small clothing items, accessories, books | Boutiques, bookstores, specialty shops |

| Large | 26 × 32 × 12 cm | Clothing, shoes, multiple small items | Fashion retailers, department stores |

| Extra Large | 31 × 42 × 12 cm | Larger clothing, multiple items, boxed products | Department stores, fashion retailers, gift shops |

| 2X Large | 36 × 45 × 15 cm | Bulky items, multiple purchases, blankets | Department stores, home goods, large retailers |

| Giant | 50 × 72 × 18 cm | Super Size | Toy shops, gift shops |

| Wine Bag | 12 × 39 × 9 cm | Wine,Spirits, specialty bottles | Liquor stores, specialty beverage shops |

| Custom Size | According to requirements | Specific products, unique shapes | Any business with specific packaging needs |

Size Selection Tips

- Choose a bag size that allows your product to fit comfortably with a small amount of extra space

- Consider whether customers will likely add more items to the bag

- For clothing, factor in the folded size rather than the hanging size

- Remember that oversized bags can make small products look insignificant

- Undersized bags can appear cheap and may damage products

- Custom sizes are available for unique products or to create a distinctive brand experience

Paper Materials Selection

Select the perfect paper material to achieve your desired look, feel, and durability.

📄 C1S Paper (Premium White Card)

High-quality single-sided coated paper for stunning print results and vibrant colors. Ideal for luxury packaging and upscale branding.

Available Paper Weights:

- ✅ Exceptional print and color quality

- ✨ Smooth, professional surface

- 🎁 Perfect for luxury packaging

- 💪 Durable and long-lasting

🖨️ C2S Art Paper (Double-Sided Coated)

Premium glossy paper for outstanding graphics and photo reproductions. Perfect for professional projects and high-end applications.

Available Paper Weights:

- ✨ Glossy finish for a premium look

- 🌈 Vibrant color reproduction

- 📑 Suitable for dual-side printing

- 🏆 Professional-grade quality

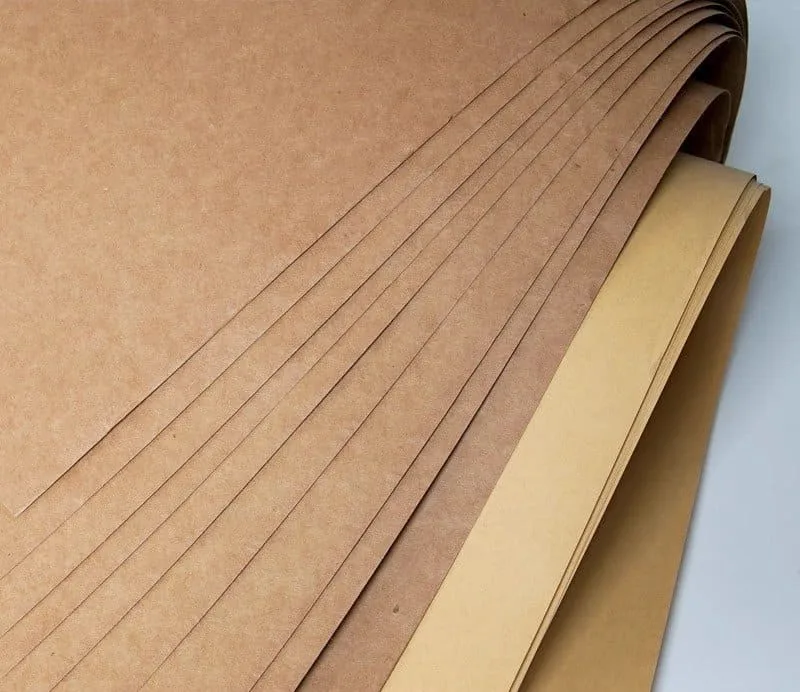

🌿 Eco-Friendly Kraft Paper

Natural, sustainable paper with rustic charm. Available in white and brown options, ideal for eco-conscious packaging and branding.

Available Paper Weights:

- 🌿 Eco-friendly and sustainable

- 📜 Rustic texture with natural appeal

- 💪 Strong and durable

- ⚪ White & brown finishes available

🌈 Premium Holographic Paper

Mesmerizing holographic paper with rainbow effects and reflective properties. Creates striking packaging for high-visibility branding.

Available Paper Weights:

- ✨ Stunning holographic visuals

- 🌈 Multi-dimensional rainbow finish

- 🎁 Ideal for luxury branding

- 👀 Eye-catching shelf presence

✨ Luxury Glitter Paper

Glitter-infused paper with dazzling metallic finish. Adds elegance and sparkle to luxury packaging for special occasions.

Available Paper Weights:

- ✨ Sparkling shimmer effects

- 💎 Metallic shine finish

- 🎉 Perfect for celebrations

- 🏆 Luxury branding appeal

🎨 Vibrant Colored Paper

High-quality paper with consistent color on both sides. Ideal for creative designs and brand-specific packaging.

Available Paper Weights:

- 🎨 Consistent color on both sides

- 🌈 Wide range of vibrant options

- 🖌️ Excellent color stability

- 📦 Perfect for custom packaging

🌟 Premium Pearlescent Paper

Elegant pearlescent paper with subtle shimmer and consistent color. Perfect for refined, upscale packaging with a premium aesthetic.

Available Paper Weights:

- ✨ Subtle pearl-like finish

- 🎨 Consistent color matching

- 💎 Sophisticated appeal

- 🏆 Ideal for luxury packaging

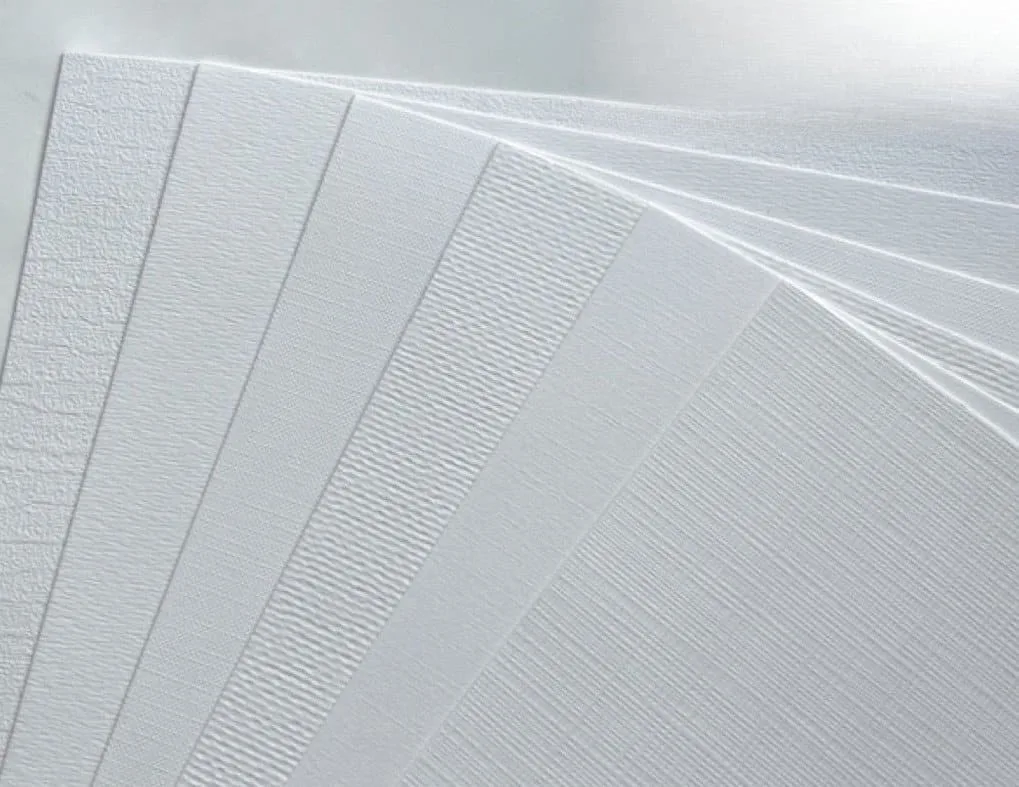

🖋️ Specialty Textured Paper

Textured paper with unique embossed patterns for a premium tactile experience. Perfect for memorable, luxury packaging designs.

Available Paper Weights:

- 🖋️ Distinctive embossed textures

- ✨ Premium tactile experience

- 💎 Sophisticated luxury appearance

- 📢 Enhanced brand differentiation

Printing Options

Choose the right printing technique to achieve your desired visual effect and brand representation.

🎨 Four-Color (CMYK) Printing

Standard full-color printing using cyan, magenta, yellow, and black inks to create a wide spectrum of colors.

Best For:

- Full-color photographs and images

- Gradients and color transitions

- Complex, multi-colored designs

- When exact color matching is not critical

Note: CMYK has a more limited color gamut than PMS colors but is more economical.

🎯 Spot Color (Pantone) Printing

Uses pre-mixed inks for exact color matching, ensuring brand colors are reproduced consistently.

Best For:

- Brand-specific colors

- 1–3 solid colors

- Metallic or fluorescent inks

- When color consistency is critical

Note: More costly for full-color images but highly accurate for solid colors.

✨ UV Printing

Uses UV light to cure ink instantly. Produces vibrant colors and allows raised printing effects.

Best For:

- High-end packaging

- Raised or special effects

- Non-absorbent materials

- Durability & scratch resistance

Note: More expensive but offers superior quality & special effects.

🖌️ Screen Printing

Mesh screens transfer ink onto paper, creating bold opaque colors and textured effects.

Best For:

- Bold, opaque colors

- Metallic/specialty inks

- Textured & thick ink effects

- Designs with limited colors

Note: Not ideal for photos, but excellent for bold graphics & effects.

Paper Bag Finishing Options

Enhance your paper bags with premium finishing techniques that add visual appeal and tactile interest.

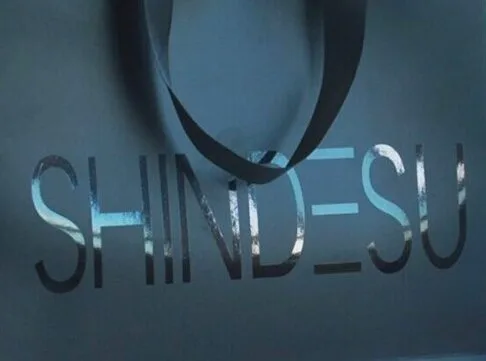

Hot Stamping

Premium metallic foil finishing using heat and pressure technology. Creates luxurious, reflective surfaces perfect for high-end packaging and branding applications.

Cold Stamping

Advanced adhesive-based foil application without heat. Ideal for temperature-sensitive materials while delivering stunning metallic effects for premium packaging solutions.

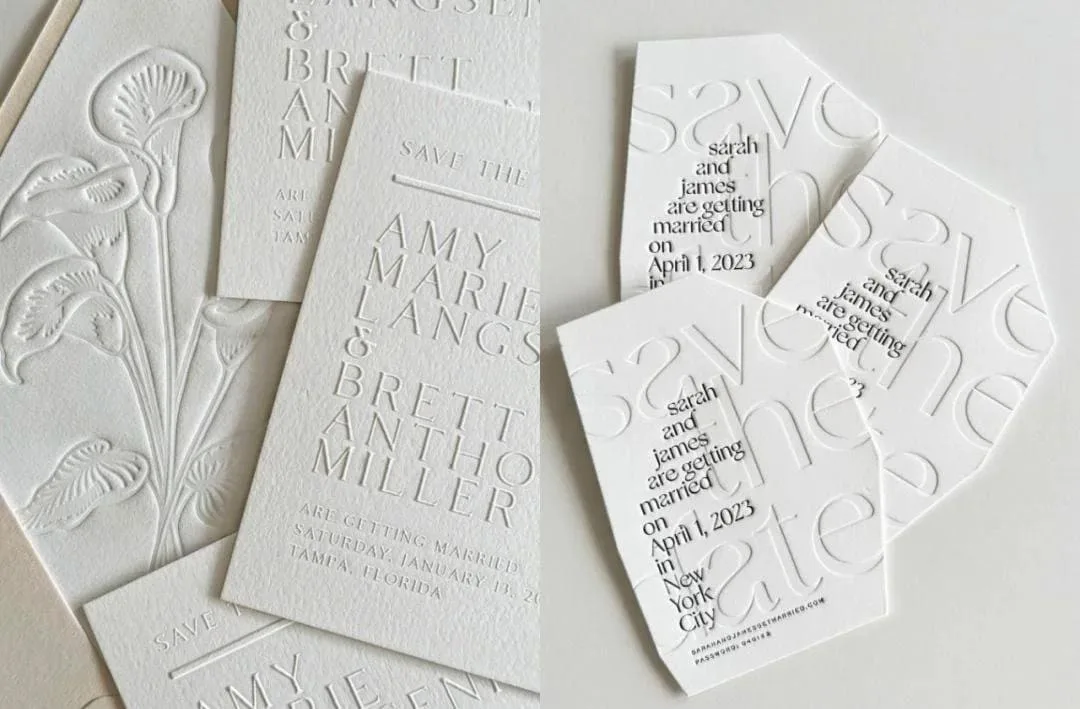

Embossing / Debossing

Three-dimensional raised or recessed design creation. Adds sophisticated tactile elements and premium brand perception to packaging materials.

Spot UV

Selective ultraviolet coating for enhanced gloss and protection. Creates striking contrast effects and premium visual appeal for targeted design elements.

Matte Lamination

Elegant non-reflective surface coating for sophisticated aesthetics. Provides durability and fingerprint resistance while maintaining premium tactile quality.

Glossy Lamination

High-gloss protective coating for vibrant color enhancement. Delivers exceptional shine and durability while making colors pop for maximum visual impact.

Glitter Effects

Sparkling decorative particles for eye-catching appeal. Perfect for festive packaging, special occasions, and brands seeking attention-grabbing visual effects.

3D Tip-on Elements

Multi-dimensional attachments for premium packaging differentiation. Creates unique tactile experiences and enhanced brand memorability through innovative design elements.

Foaming Effects

Heat-activated expandable inks creating raised, textured surfaces. Adds playful dimension and unique tactile interaction for memorable brand experiences.

Flocking Texture

Luxury velvet-like fiber application for premium tactile experiences. Creates sophisticated soft-touch surfaces that enhance perceived value and brand prestige.

Laser Cutting

Precision laser technology for intricate pattern creation. Enables complex geometric designs and custom shapes for truly unique packaging solutions.

Premium

Premium

Multi-Process Combination

Ultimate luxury finishing combining multiple techniques. Integrates embossing, foil stamping, UV coating, and specialty effects for unparalleled premium packaging excellence.

Premium Paper Bag Handle Options

Choose from our extensive collection of high-quality paper bag handles. Each option is carefully crafted to enhance your brand's packaging aesthetics while ensuring optimal functionality and durability.

Satin Ribbon Handles

Premium satin ribbon handles that elevate your packaging with luxury appeal. Perfect for high-end retail, fashion, and gift packaging applications.

Grosgrain Ribbon Handles

Structured grosgrain ribbon with distinctive ribbed texture. Offers superior durability and sophisticated appearance for premium packaging solutions.

PP Rope Handles

Heavy-duty polypropylene twisted rope handles engineered for maximum strength. Ideal for retail packaging requiring superior weight-bearing capacity.

Organza Handles

Delicate sheer organza ribbon handles that create an ethereal, feminine aesthetic. Perfect for wedding favors, jewelry, and luxury cosmetics packaging.

Cotton Handles

Sustainable twisted cotton handles offering natural, organic appeal. Ideal for eco-conscious brands and artisanal product packaging applications.

Paper Rope Handles

Coordinated twisted paper rope handles crafted from matching bag materials. Creates seamless, integrated packaging design with eco-friendly benefits.

Die-cut Handles

Clean, minimalist handles precision-cut directly from bag material. Offers streamlined aesthetics without additional components or materials.

Custom Special Handles

Bespoke handle solutions designed to your exact specifications. Create distinctive, brand-exclusive packaging that sets your products apart from competitors.

Ready to Choose Your Perfect Handle?

Get expert consultation on handle selection and receive a customized quote for your paper bag packaging needs.

Paper Bag Cost Analysis

Understanding the factors that influence paper bag pricing to help you make informed decisions.

Product Cost Factors

Quantity

- • Higher quantities = lower unit cost

- • Setup costs are amortized across the order

- • Production efficiencies increase with volume

Size & Shape

- • Larger bags require more material

- • Complex shapes increase production time

- • Custom sizes require special tooling

Materials

- • Paper type and weight affect cost

- • Specialty papers (holographic, glitter) cost more

- • Higher GSM = higher material cost

Printing & Finishing

- • Number of colors impacts cost

- • Special finishes (foil, embossing) add expense

- • Coverage area affects ink usage

Handles

- • Premium handles (ribbon, cotton) cost more

- • Handle attachment method affects labor cost

- • Die-cut handles may be most economical

Complexity

- • Multiple finishing techniques increase cost

- • Custom structural elements add expense

- • Special assembly requirements impact labor

Shipping & Additional Costs

Shipping Considerations

- • Ocean freight: Most economical but longest transit time (30-55 days)

- • Air freight: Higher cost but faster delivery (10-15 days)

- • Express courier: Highest cost for fastest delivery (7-10 days)

- • Dimensional weight may impact shipping costs

- • Consolidation opportunities can reduce per-unit shipping cost

Additional Costs

- • Customs duties and import taxes

- • Sample development and approval

- • Packaging for shipping protection

- • Quality control inspections

- • Storage costs for inventory

- • Design services and artwork preparation

Cost Optimization Tips

- • Order in larger quantities when possible to reduce unit costs

- • Consider standard sizes to avoid custom tooling charges

- • Limit the number of colors and special finishes if budget is a concern

- • Plan ahead to avoid rush charges and expedited shipping

- • Consolidate shipments to reduce freight costs

- • Balance quality requirements with budget constraints

Paper Bag Production Timeline

Understanding the timeframe for custom paper bag production and delivery to plan your projects effectively.

Initial Preparation

Design confirmation, material selection, and production planning

1-3 days

-

Finalize design specifications

-

Select materials and finishes

-

Prepare production files

-

Create pre-production samples

-

Test structural integrity

-

Verify colors and finishes

Sampling

Creating and approving pre-production samples

7-10 days

Deposit Payment

Processing deposit payment to initiate production

1-3 days

-

Receive invoice for deposit (30-50%)

-

Process payment via T/T or other methods

-

Confirm production schedule

-

Raw material preparation

-

Printing and die-cutting

-

Finishing and quality control

Mass Production

Manufacturing your packaging products at scale

25-35 days

Shipping

Delivery of finished products to your destination

Sea: 30-55 days | Air: 10-15 days | Express: 7-10 days

-

Balance payment and shipping arrangement

-

Export documentation and customs clearance

-

Tracking and delivery coordination

Want to Compress Delivery Time?

We offer several strategies to reduce the overall timeline for urgent projects:

Express Sample Service

Reduce sample production to 3-5 days with our expedited service for urgent projects.

Pre-approved Materials

Select from our in-stock materials to eliminate material procurement time.

Parallel Processing

We can begin material preparation while samples are being approved to save time.

Premium Shipping Options

Expedited air freight and courier services can significantly reduce transit time.

Custom Paper Bag Common Pitfalls

Avoid these common mistakes when designing and ordering custom paper bags to ensure a successful project.

Underestimating Material Requirements

Selecting paper that's too thin for the intended use can lead to tearing, poor durability, and a cheap appearance.

How to Avoid:

- Consider the weight of items the bag will carry

- Request material samples before finalizing your order

- Follow recommended GSM guidelines for your bag size and use

Incorrect Size Specifications

Ordering bags that are too small or too large for your products wastes money and creates a poor customer experience.

How to Avoid:

- Measure your products carefully, including packaging

- Add a small allowance for easy insertion and removal

- Request a physical sample to test with actual products

Poor Artwork Preparation

Low-resolution images, incorrect color specifications, or improper file formats can result in blurry, off-color printing.

How to Avoid:

- Use high-resolution images (300 DPI minimum)

- Provide artwork in vector format when possible

- Specify colors using Pantone (PMS) codes for accuracy

- Include bleed and safe zones in your design files

Ignoring Handle Strength

Selecting handles that aren't strong enough for the intended weight can lead to breakage and customer dissatisfaction.

How to Avoid:

- Match handle type to the expected weight of contents

- Consider reinforced handle attachments for heavier items

- Test sample bags with realistic product weights

Insufficient Lead Time

Not allowing enough time for production and shipping can result in rushed decisions, higher costs, and quality compromises.

How to Avoid:

- Plan projects at least 2-3 months in advance

- Build in buffer time for sample revisions and shipping delays

- Communicate timeline requirements clearly from the start

Overlooking Environmental Factors

Failing to consider how bags will be stored or used can lead to problems with moisture, temperature, or UV exposure.

How to Avoid:

- Consider where and how bags will be stored and used

- Select appropriate coatings or laminates if needed

- Test materials in the intended environment

Neglecting Quality Control

Skipping thorough quality checks can result in receiving bags with defects, inconsistencies, or other issues.

How to Avoid:

- Request pre-production samples for approval

- Specify quality standards in your order requirements

- Consider third-party inspection for large orders

Focusing Only on Price

Choosing the lowest-cost option without considering quality and service can lead to disappointment and hidden costs.

How to Avoid:

- Evaluate suppliers based on quality, service, and price

- Request references and sample work from potential suppliers

- Consider the total cost of ownership, not just unit price

Why Choose Us

Discover the advantages of partnering with us for your custom paper bag needs.

Quality Excellence

We maintain rigorous quality control standards at every stage of production. Our facilities are equipped with advanced machinery and staffed by skilled craftspeople with years of experience in paper bag manufacturing.

Sustainability Commitment

Environmental responsibility is at the core of our business. We offer FSC-certified papers, use eco-friendly inks, and continuously work to reduce waste and energy consumption in our manufacturing processes.

Exceptional Service

Our dedicated account managers provide personalized support throughout your project. We pride ourselves on clear communication, prompt responses, and going the extra mile to ensure your complete satisfaction.

Design Expertise

Our in-house design team can help bring your vision to life or create custom concepts tailored to your brand. We stay current with packaging trends and innovative techniques to make your bags stand out.

Global Capabilities

With manufacturing facilities strategically located and established shipping partners worldwide, we efficiently serve clients across the globe. We handle all logistics details to ensure smooth delivery to your location.

Competitive Pricing

Our efficient production processes and direct manufacturing capabilities allow us to offer excellent value without compromising quality. We provide transparent pricing with no hidden costs.

Manufacturing Capabilities

Our state-of-the-art facilities can handle orders of any size with consistent quality. We offer a comprehensive range of printing, finishing, and customization options all under one roof.

Reliable Timelines

We understand the importance of meeting your deadlines. Our production planning and quality control systems ensure on-time delivery without sacrificing attention to detail.

Industry Experience

With over 10 years in the packaging industry, we've developed expertise across various sectors including retail, fashion, cosmetics, food, and more. We understand the unique requirements of different industries.

Certifications

Our commitment to quality, sustainability, and ethical practices is backed by internationally recognized certifications.

FSC Certification

The Forest Stewardship Council certification ensures that products come from responsibly managed forests that provide environmental, social, and economic benefits.

- Ensures paper comes from responsibly managed forests

- Protects biodiversity and indigenous peoples' rights

- Chain of custody verification throughout the supply chain

BSCI Certification

The Business Social Compliance Initiative certification verifies that our facilities maintain fair and ethical working conditions in accordance with international standards.

- Ensures fair compensation and working hours

- Prohibits discrimination and child/forced labor

- Promotes occupational health and safety

Additional Quality Standards

Product Safety Testing

Our products undergo rigorous testing for harmful substances and comply with international safety standards including REACH and CPSIA requirements.

Environmental Management

Our facilities follow environmental management practices aligned with ISO 14001 standards, focusing on waste reduction and energy efficiency.

Quality Management

We implement comprehensive quality management systems that ensure consistent product quality and continuous improvement in our processes.

Client Success Stories

Discover how Omet's custom paper bags have transformed businesses across industries

Sarah Mitchell

Gift Shop Owner, London

"Omet's custom paper bags elevated our gift presentation completely. The quality is exceptional, and our customers constantly compliment the elegant designs. Their FSC certification aligns perfectly with our sustainability values."

Marco Rodriguez

Restaurant Chain Manager, Barcelona

"Our takeaway business transformed with Omet's food-grade paper bags. They're sturdy, grease-resistant, and showcase our brand beautifully. Customer satisfaction increased significantly since we switched to their premium packaging."

Elena Petrov

Jewelry Boutique Owner, Paris

"The luxury feel of Omet's custom paper bags perfectly matches our high-end jewelry pieces. The attention to detail in finishing and the premium materials make every purchase feel like a special occasion for our clients."

Aria Chen

Beauty Brand Director, Singapore

"Omet delivered exactly what our cosmetics line needed - stylish, Instagram-worthy bags that our customers love to show off. The hot stamping finish adds that premium touch that sets us apart from competitors."

James Thompson

Fashion Retailer, New York

"The durability and design flexibility of Omet's paper bags have been game-changing for our fashion store. They handle heavy clothing items perfectly, and the custom branding makes every purchase memorable."

Lisa Wang

E-commerce Manager, Toronto

"Omet's custom paper bags revolutionized our unboxing experience. Our online customers now share photos of their deliveries on social media, creating organic marketing. The cost-effectiveness surprised us too!"

Ready to Transform Your Brand Packaging?

Join thousands of satisfied customers who trust Omet for their custom paper bag solutions. Tell us your needs, we'll deliver surprises.

Frequently Asked Questions

Find answers to common questions about our custom paper bag services.

What is the minimum order quantity for custom paper bags?

Our minimum order quantity is typically 1,000 pieces. However, we can accommodate smaller orders for certain standard sizes and designs. Contact us to discuss your specific requirements.

How long does production take?

Standard production time is 15-20 business days after design approval and payment confirmation. Rush orders can be accommodated with shorter timelines, subject to additional charges.

What paper materials do you offer?

We offer various paper options including kraft paper, art paper, coated paper, and specialty papers. All materials are FSC certified and available in different weights and finishes to suit your needs.

Can you provide design services?

Yes, our experienced design team can create custom designs based on your brand requirements. We offer free design consultation and can work with your existing artwork or create new designs from scratch.

What printing methods are available?

We offer various printing options including offset printing, digital printing, flexographic printing, and specialty finishes like hot stamping, embossing, and UV coating for enhanced visual appeal.

Do you offer samples before mass production?

Absolutely! We provide physical samples for approval before proceeding with mass production. Sample fees may apply but are often deducted from the final order total.

What are your shipping and delivery options?

We offer flexible shipping options including sea freight, air freight, and express delivery. Our logistics team will recommend the most cost-effective solution based on your timeline and budget.

Are your products eco-friendly and sustainable?

Yes, we prioritize sustainability. All our paper materials are FSC certified, and we use eco-friendly inks and adhesives. We're BSCI certified and committed to responsible manufacturing practices.

How do I get a quote for my custom paper bags?

Simply contact us with your requirements including quantity, size, material preferences, and design details. Our team will provide a detailed quote within 24 hours, including all costs and timeline.

What quality control measures do you have in place?

We maintain strict quality control throughout production with multiple inspection points, automated testing equipment, and final quality checks before shipping. We guarantee products meet agreed specifications.

Still Have Questions?

Our expert team is ready to help you find the perfect custom paper bag solution for your business needs.