Custom Paper Box manufacturer

- Complete Box Packaging Solutions

Everything you need to know about custom paper box packaging. From design to delivery, we've got you covered with professional insights and premium solutions.

Complete Directory

On this page, you can explore comprehensive information about paper box customization. Click on each directory item to read detailed content and fully understand our paper box solutions to help you customize a satisfactory packaging solution.

Custom Cases

Real project examples and success stories

Box Structure

Various box types and configurations

MOQ

Minimum order quantities and pricing

Box Sizes

Dimensions and size recommendations

Material Selection

Paper types and material options

Printing Options

Various printing techniques available

Process Selection

Finishing and enhancement processes

Inner Support

Protection and organization inserts

Accessories

Additional components and features

Cost Analysis

Pricing breakdown and factors

Timeline Estimate

Production and delivery schedules

Common Pitfalls

Avoid these common mistakes

Why Us

Our competitive advantages

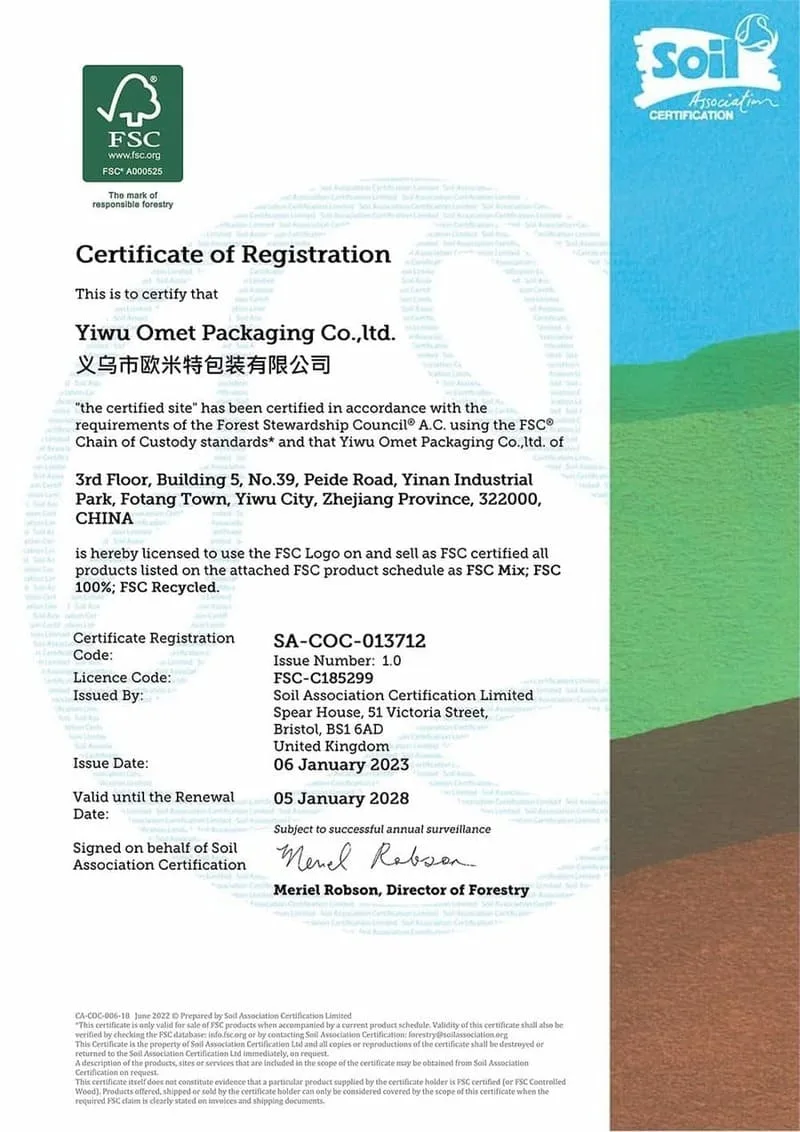

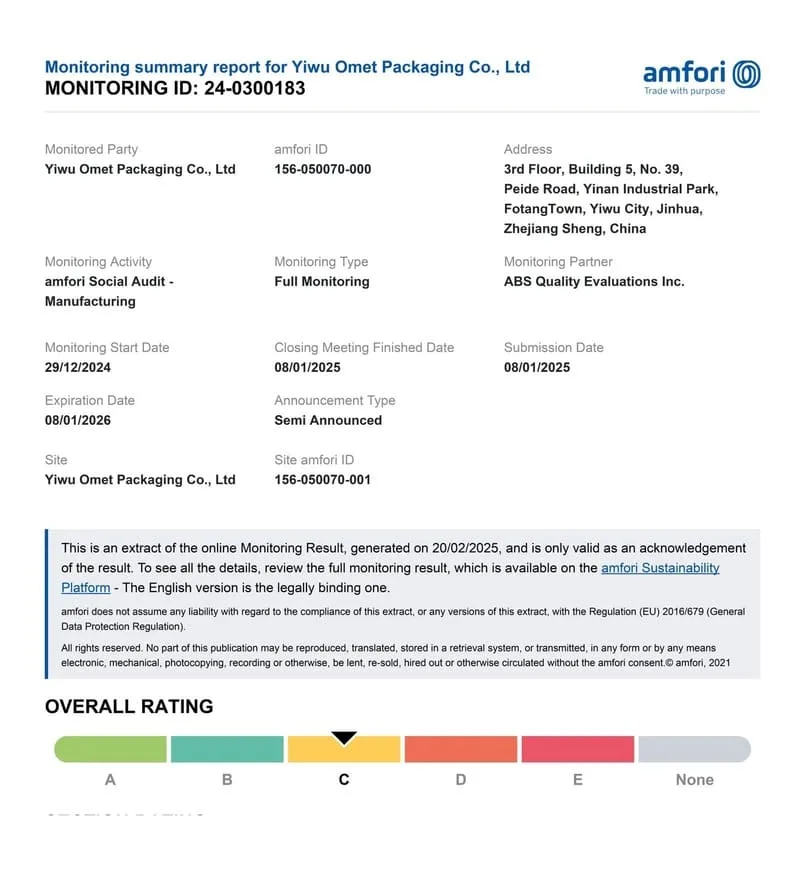

Certificates

Quality and compliance certifications

Customer Reviews

What our clients say about our services

FAQ

Frequently asked questions

Related Products

Complementary packaging solutions

Ready to Create Your Custom Packaging?

Share size, quantity, materials, and finishes. Our engineer team will return pricing, timeline, and packaging suggestions tailored to your brand.Custom Box Case Studies

Explore our successful packaging solutions across various industries. Each project showcases our expertise in creating custom boxes that enhance product presentation

Custom Logo Boxes

Professional custom packaging boxes featuring your brand logo and colors for enhanced brand recognition and marketing impact.

Explore More →

Gift Packaging Boxes

Elegant gift boxes, bags, and wrapping solutions for special occasions and corporate gifts.

Explore More →

Food Packaging Boxes

Food-grade packaging solutions for restaurants, bakeries, and food service businesses.

Explore More →

Floral Packaging Boxes

Beautiful wrapping and presentation solutions for florists and flower arrangements.

Explore More →

Cosmetic Packaging Boxes

Premium packaging for beauty products, skincare, and cosmetic brands.

Explore More →

Jewelry Packaging Boxes

Luxurious packaging solutions for fine jewelry, watches, and precious accessories.

Explore More →

Shipping Packaging Boxes

Durable and protective packaging for safe product transportation and delivery.

Explore More →

Wine Packaging Boxes

Elegant wine packaging solutions for wineries, wine retailers, and gift presentations with premium protection.

Explore More →

Electronics Packaging Boxes

Protective electronics packaging solutions for smartphones, computers, gadgets, and electronic accessories.

Explore More →

Other Product Packaging

Custom solutions for electronics, pharmaceuticals, textiles, and specialty products.

Explore More →

More Custom Paper Boxes

Professional custom paper boxes featuring your brand logo and colors for enhanced brand recognition and marketing impact.

Explore More →

Custom Design Service

Professional design team ready to create unique packaging solutions for your brand.

Box Structures Types

Choose the perfect box structure for your products. Each design offers unique benefits and presentation styles to showcase your items effectively.

Lid and Base Boxes

Premium two-piece packaging with separate lid and base construction, ideal for luxury retail merchandise and high-end gift presentation solutions.

Drawer Paper Boxes

Sophisticated sliding drawer boxes with smooth-glide mechanism, perfect for premium product packaging and elegant gift presentations with enhanced user experience.

Flip Top Boxes

Magnetic closure flip-top boxes with premium finishing options, designed for luxury brands seeking sophisticated packaging solutions that enhance brand perception and customer experience.

Rigid Folding Boxes

Collapsible rigid boxes offering easy assembly and space-efficient storage, reducing shipping costs by 40% while maintaining premium brand credibility and structural integrity.

Paper Tube Boxes

Eco-friendly cylindrical packaging with sustainable materials and elegant design, perfect for cosmetics, spirits, and luxury goods while boosting environmental brand perception.

Tray and Sleeve Boxes

Secure dual-component packaging with protective tray and sleeve design, providing optimal product containment while offering convenient access and professional presentation.

Double Door Boxes

Theatrical dual-opening boxes creating dramatic product reveals, designed for memorable unboxing experiences that enhance customer engagement and social media sharing potential.

Paper Basket Boxes

Sustainable carry-handle basket boxes with eco-friendly construction, ideal for gourmet gifts and retail displays that boost customer convenience and environmental appeal.

Pillow Boxes

Curved pillow-shaped gift boxes with elegant silhouette, specifically designed for jewelry, cosmetics, and small accessories with ribbon-ready construction for premium presentation.

Advent Calendar Boxes

Interactive 24-compartment countdown packaging driving December sales surge and viral social sharing, perfect for confectionery brands and seasonal marketing campaigns.

Nested Paper Boxes

Space-optimized stackable box sets reducing warehouse costs by 30%, featuring multi-layered component protection and efficient logistics for bulk packaging solutions.

Desktop Organizer Boxes

Multi-compartment desktop storage solutions with premium paper construction, designed for office organization, stationery storage, and workspace efficiency enhancement.

Cardbooard Boxes

Cost-effective recyclable cardboard packaging reducing overall packaging expenses by 35%, suitable for all industries with sustainable materials and versatile applications.

Corrugated Mailer Boxes

Self-locking corrugated shipping boxes with crush-resistant edges, reducing shipping damage by 90% and ensuring secure e-commerce delivery protection.

Paper Suitcase Boxes

Premium carry-handle suitcase-style boxes transforming retail gifts into viral unboxing experiences, featuring durable construction and Instagram-worthy presentation design.

Multi Shaped Boxes

Custom geometric packaging solutions with unique shapes and creative designs, perfect for brand differentiation and memorable product presentation across various industries.

Minimum Order Quantity (MOQ)

In the printing industry, quantity is one of the most important factors affecting price. The more you order, the more cost-effective the price becomes. Our MOQ is 500 pieces per design/size, but the price will be relatively high. Orders of 3,000 pieces offer more reasonable pricing, while quantities of 5,000 or even 10,000 pieces provide the most competitive rates.

Starting point for custom orders

Balanced cost and quantity

Best value for money

Maximum cost savings

Important Considerations

-

MOQ applies per design/size combination

-

Different designs or sizes cannot be combined to meet MOQ

-

Setup costs are amortized over larger quantities, reducing unit price

-

Storage considerations should be factored into your order quantity decision

Paper Box Sizes & Applications

Selecting the right box size is crucial for product presentation and protection. Here's a guide to common dimensions and their suitable applications.

Small Boxes

Perfect for jewelry, small electronics, and accessories

- • Jewelry boxes: 8×8×3 cm

- • Ring boxes: 5×5×4 cm

- • Earphone boxes: 12×10×5 cm

- • Watch boxes: 15×12×8 cm

- • Small gift boxes: 10×10×10 cm

Medium Boxes

Ideal for cosmetics, small appliances, and books

- • Cosmetic boxes: 20×15×8 cm

- • Phone boxes: 18×12×6 cm

- • Shoe boxes: 30×20×12 cm

- • Book boxes: 25×18×5 cm

- • Gift boxes: 25×25×15 cm

Large Boxes

Great for clothing, large electronics, and bulk items

- • Clothing boxes: 40×30×15 cm

- • Laptop boxes: 45×35×8 cm

- • Gift sets: 50×35×20 cm

- • Product bundles: 45×30×25 cm

- • Shipping boxes: 40×40×30 cm

Extra Large Boxes

Perfect for bulk orders, large products, and storage

- • Storage boxes: 60×40×30 cm

- • Bulk packaging: 80×60×40 cm

- • Display boxes: 70×50×35 cm

- • Shipping containers: 100×80×50 cm

- • Custom large items: Variable

Specialty Sizes

Tailored dimensions for unique products and requirements

- • Wine bottles: 35×10×10 cm

- • Poster tubes: 60×8×8 cm

- • Long items: 100×15×10 cm

- • Flat packages: 40×30×2 cm

- • Irregular shapes: Custom design

Size Guidelines

Important considerations for choosing the right size

- • Add 5-10mm padding space

- • Consider insert thickness

- • Account for closure mechanisms

- • Think about shipping efficiency

- • Plan for product variations

Important Considerations

-

MOQ applies per design/size combination

-

Different designs or sizes cannot be combined to meet MOQ

-

Setup costs are amortized over larger quantities, reducing unit price

-

Storage considerations should be factored into your order quantity decision

Paper Box Material Selection

The right material choice is essential for creating the perfect packaging experience. Explore our range of high-quality materials for your custom boxes.

Rigid Box Materials

Base Structure

800-2500gsm Grey Cardboard

Outer Wrapping

120-150gsm Coated Paper, Kraft Paper, or Textured Paper

Best For

- Luxury products

- High-end retail packaging

- Premium gift boxes

- Products requiring maximum protection

Key Benefits

- Superior durability and strength

- Premium look and feel

- Excellent printing surface

- Supports various finishing techniques

Folding Box Materials

Material Options

250-400gsm Coated Paper, Kraft Paper, or Textured Paper

Common Finishes

Gloss, Matte, Soft-Touch, Metallic

Best For

- Retail products

- Cosmetics and beauty

- Food and confectionery

- Products with moderate protection needs

Key Benefits

- Cost-effective production

- Flat shipping and storage

- Versatile design options

- Environmentally friendly options available

Corrugated Box Materials

Outer Layer

200gsm Coated Paper, Kraft Paper, or Textured Paper

Inner Structure

Corrugated Flute Board (E-flute, B-flute, etc.)

Best For

- E-commerce shipping

- Subscription boxes

- Heavier products

- Products requiring cushioning

Key Benefits

- Superior protection during shipping

- Lightweight yet strong

- Eco-friendly options available

- Cost-effective for larger quantities

Paper Box Printing Options

Choose the perfect printing technique to bring your packaging design to life. Each method offers unique advantages for different applications and visual effects.

Four Color Printing (CMYK)

Standard full-color printing process using cyan, magenta, yellow, and black inks to create a wide spectrum of colors.

Best For:

-

Photographic images

-

Colorful designs

-

Cost-effective color reproduction

Spot Color Printing (PMS)

Precise color matching using pre-mixed inks for exact brand colors and special effects not achievable with CMYK.

Best For:

-

Brand color consistency

-

Metallic and fluorescent colors

-

Designs with 1-3 specific colors

UV Printing

Ultraviolet-cured printing that creates vibrant colors and allows for special effects like high-gloss spot finishes.

Best For:

-

High-end packaging

-

Vibrant color reproduction

-

Designs requiring durability

Screen Printing

Technique that applies thick layers of ink through a mesh screen, creating bold colors and tactile effects.

Best For:

-

Textured effects

-

Opaque colors on dark surfaces

-

Special inks (metallic, glow-in-dark)

Printing Considerations

Color Management

Ensuring consistent color reproduction is crucial for brand identity:

-

We provide color proofs before production

-

PMS color matching available for brand consistency

-

Color calibration across different materials

Design Requirements

For optimal printing results, we recommend:

-

300 DPI resolution for all images

-

CMYK color mode for standard printing

-

3mm bleed and safety margins in artwork

Paper Box Finishing Processes

Elevate your packaging with premium finishing techniques that enhance visual appeal and create tactile experiences for your customers.

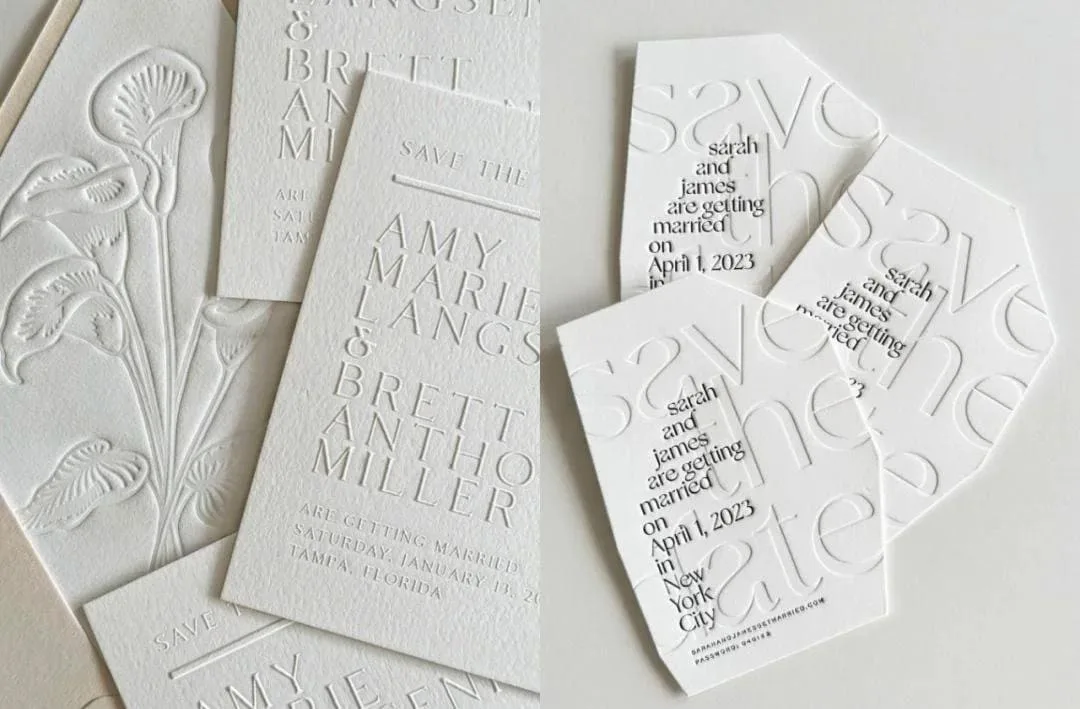

Hot Stamping

Enhance your products with premium metallic foil finishing, crafted using advanced heat and pressure technology. Ideal for creating luxurious, reflective surfaces that elevate high-end packaging and branding.

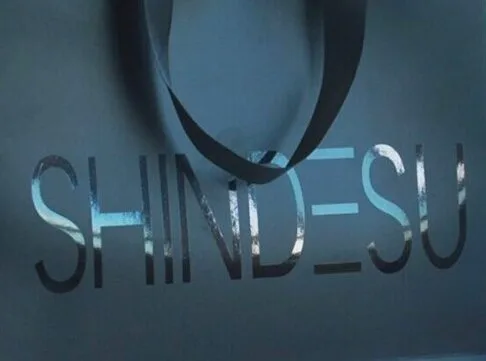

Cold Stamping

A cutting-edge technique utilizing adhesive-based foil application without heat, perfect for temperature-sensitive materials. Achieve brilliant metallic finishes to elevate premium packaging designs.

Embossing and Debossing

Enhance your packaging with three-dimensional raised or recessed designs. These techniques add a touch of sophistication, boost tactile engagement, and elevate your brand's premium appeal.

Spot UV

Elevate your designs with selective ultraviolet coating, offering enhanced gloss, superior protection, and eye-catching contrast effects. Perfect for adding a premium visual appeal to specific design elements.

Matte Lamination

Enhance your product with an elegant, non-reflective surface coating designed for sophisticated aesthetics. Experience superior durability, fingerprint resistance, and a premium tactile feel.

Glossy Lamination

Enhance your designs with high-gloss protective coating for vivid colors and unmatched durability. Achieve stunning shine and make your visuals stand out effortlessly.

Glitter Effects

Add a touch of sparkle with glitter effects that captivate attention. Ideal for enhancing festive packaging, celebrating special occasions, and creating visually stunning branding.

<

<

3D Tip-on Elements

Discover multi-dimensional attachments designed to elevate premium packaging. Enhance tactile experiences and boost brand recognition with cutting-edge design innovations.

Foaming Effects

Discover heat-activated expandable inks that produce raised, textured surfaces. Enhance brand recognition with playful dimensions and unique tactile interactions for unforgettable experiences.

Flocking Texture

Experience the ultimate in luxury with velvet-like fiber applications. These premium soft-touch surfaces elevate tactile sensations while boosting perceived value and brand prestige.

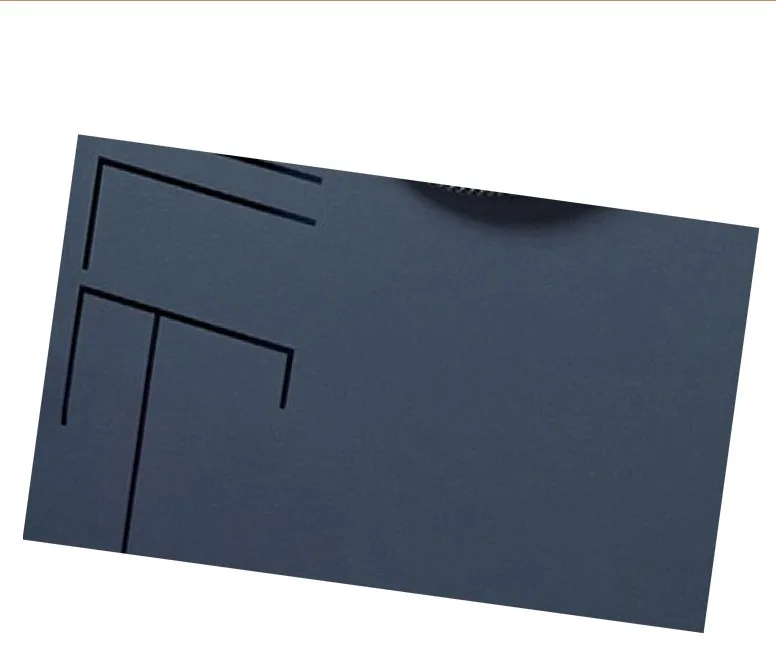

Laser Cutting

Advanced precision laser technology designed for crafting intricate patterns. Perfect for creating complex geometric designs and custom shapes, delivering exceptional and unique packaging solutions.

Multi-Process Combination

Experience the pinnacle of luxury finishing with a masterful blend of techniques. Featuring embossing, foil stamping, UV coating, and specialty effects, this approach delivers unmatched premium packaging solutions.

Paper Box Inner Support Options

Protect your products and enhance presentation with custom inner packaging solutions. Choose the right material to secure items and create a complete unboxing experience.

Blister Tray

Clear plastic formed packaging that provides excellent product visibility and protection.

Key Features:

- • Crystal clear product visibility

- • Tamper-evident protection

- • Lightweight and cost-effective

- • Perfect product fit

Best For:

Small electronics, toys, hardware, pharmaceuticals, retail products

PET Tray

Rigid plastic trays that provide excellent organization and protection for multiple items.

Key Features:

- • Durable and reusable

- • Excellent organization

- • Chemical resistant

- • Food-safe material

Best For:

Cosmetics, food products, multi-component sets, premium packaging

EVA Tray

Flexible foam material that provides excellent shock absorption and custom-fit protection.

Key Features:

- • Superior shock absorption

- • Custom cut to any shape

- • Lightweight and flexible

- • Available in various colors

Best For:

Electronics, fragile items, tools, instruments, luxury goods

Sponge Tray

Soft, compressible foam that provides gentle cushioning and protection for delicate items.

Key Features:

- • Soft and gentle protection

- • Highly compressible

- • Cost-effective solution

- • Easy to cut and shape

Best For:

Glassware, ceramics, delicate items, general cushioning

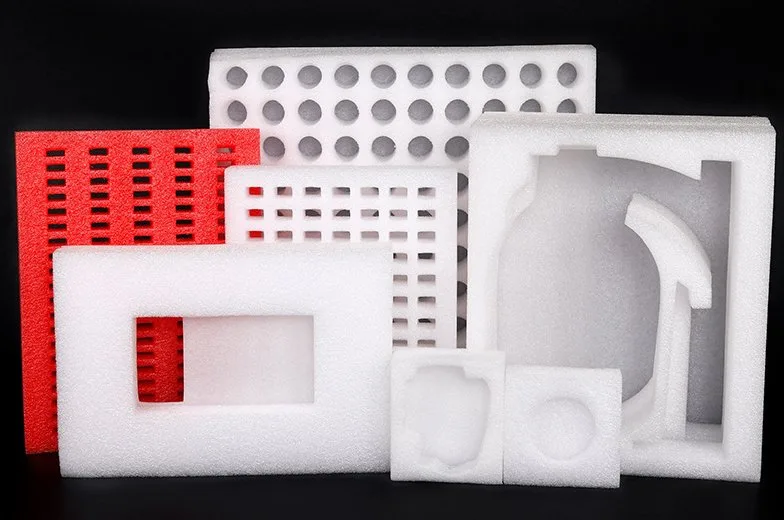

EPE Tray

High-density foam with excellent shock absorption and moisture resistance properties.

Key Features:

- • Excellent shock absorption

- • Moisture resistant

- • Lightweight yet durable

- • Eco-friendly material

Best For:

Shipping protection, electronics, furniture, appliances

Paper Tray

Eco-friendly cardboard inserts that provide organization and basic protection.

Key Features:

- • 100% recyclable material

- • Cost-effective solution

- • Easy to customize

- • Printable surface

Best For:

Food packaging, cosmetics, light items, eco-conscious brands

Paper Box Accessories

Enhance your packaging with functional and decorative accessories that add value and improve the user experience. These finishing touches can transform ordinary boxes into memorable packaging

Magnets

Strong magnetic closures for premium box experience

Ribbon

Elegant ribbon decoration for gift presentation

PVC Window

Clear windows for product visibility

Paper Sleeve

Additional paper wrapper for extra protection

Handle

Carrying handles for convenient transportation

Metal Badge

Premium metal badges for brand enhancement

Custom Paper Box Cost Analysis

Understanding the factors that influence packaging costs helps you make informed decisions that balance budget considerations with your branding and product protection needs.

Primary Cost Factors

Quantity

Higher quantities significantly reduce per-unit costs due to economies of scale in setup, materials, and production efficiency.

Size & Dimensions

Larger boxes require more materials and may incur higher shipping costs. Custom sizes may require special tooling or setup charges.

Materials

Material quality, thickness, and type significantly impact costs. Premium papers, higher GSM boards, and specialty materials increase pricing.

Printing & Finishes

Special printing techniques (like Pantone colors), multiple finishes (foil stamping, embossing), and complex designs increase production costs.

Inserts & Accessories

Custom inserts, magnetic closures, ribbons, and other accessories add to both material and assembly costs.

Production Timeline

Rush orders typically incur premium charges. Planning ahead for standard production timelines can reduce costs significantly.

Shipping & Additional Costs

Shipping Considerations

Sea Freight

- Most economical for large quantities

- Transit time: 30–55 days

- Costs depend on volume, weight, and destination

- Requires advance planning

Air Freight

- Faster delivery: 10–15 days

- Higher cost than sea freight

- Weight is a major factor

- Best for urgent or lighter shipments

Additional Fees to Consider

- Design and pre-production sample charges

- Tooling or die-cutting setup fees (often one-time)

- Import duties and taxes (vary by country)

- Warehousing and storage fees

- Insurance costs for high-value shipments

Custom Box Production Timeline

Understanding the typical timeline for custom box production helps you plan your product launches and marketing campaigns effectively.

Production Process

Preparation Work

Design confirmation, material sourcing, production planning

Sample Production

Create samples for approval, revisions if needed

Payment Processing

Deposit payment and production order confirmation

Mass Production

Full-scale production, quality control, packaging

Shipping Options

Choose your preferred shipping method

Timeline Visualization

Want to Know How to Compress Delivery Time?

We offer several options to expedite your order and reduce overall timeline:

- • Express sampling: 3-5 days instead of 7-10

- • Rush production: 15-20 days instead of 25-35

- • Air freight priority: 5-7 days instead of 10-15

- • Pre-approved materials: Skip material approval

Common Packaging Box Pitfalls

Avoid these common mistakes to ensure your custom packaging project runs smoothly and delivers the results you expect.

Inadequate Size Planning

Products may not fit properly if exact dimensions are overlooked.

Issues

- • Ignoring variations

- • Forgetting insert thickness

- • Overlooking closure space

Solution

Add 5–10mm buffer and provide samples for testing.

Color Matching Expectations

Screen colors rarely match print results exactly.

Issues

- • Expecting screen match

- • No Pantone reference

- • Skipping sample approval

Solution

Request samples & provide Pantone codes for brand colors.

Hidden Cost Surprises

Unit price alone is misleading without setup, mold, and shipping fees.

Issues

- • Ignoring setup fees

- • Not calculating shipping

- • Overlooking rush charges

Solution

Request a full cost breakdown before confirming orders.

Unrealistic Timeline Expectations

Production and shipping require buffer time to avoid last-minute stress.

Issues

- • No time for samples

- • Expecting instant production

- • Ignoring shipping delays

Solution

Plan backward from deadlines with revision buffer time.

Insufficient Communication

Vague or missing specifications lead to errors and costly revisions.

Issues

- • Vague design descriptions

- • Missing technical specs

- • Unclear expectations

Solution

Provide detailed specs, reference images & clear updates.

Skipping Quality Checks

Without inspections or samples, you risk substandard products.

Issues

- • Skipping sample approval

- • No progress photos

- • Avoiding inspections

Solution

Approve samples & consider third-party inspections for bulk orders.

Why Choose Us

Partner with a packaging manufacturer that combines expertise, quality, and service to deliver exceptional custom packaging solutions.

10+ Years Experience

Extensive experience in custom packaging solutions with thousands of successful projects completed worldwide.

Advanced Equipment

State-of-the-art printing and manufacturing equipment ensuring consistent quality and precision in every order.

Expert Team

Professional designers and quality control specialists dedicated to bringing your vision to life perfectly.

Quality Guarantee

Rigorous quality control processes and 100% satisfaction guarantee on all our products and services.

Global Shipping

Reliable worldwide shipping with tracking and insurance, ensuring your products arrive safely and on time.

24/7 Support

Round-the-clock customer support to answer your questions and provide assistance throughout your project.

What Our Clients Say

Trusted by industry leaders worldwide for quality packaging solutions that enhance brand value

"Omet's custom gift boxes exceeded our expectations. The quality is exceptional and their team understood exactly what we needed for our luxury gift line. Fast delivery and competitive pricing made this partnership perfect."

Sarah Mitchell

Procurement Manager, Luxury Gifts Co.

"We needed FSC certified food packaging for our organic product line. Omet delivered exactly what we required with excellent food-safe materials. Their expertise in food packaging regulations saved us time and ensured compliance."

Michael Chen

Supply Chain Director, Organic Foods Ltd.

"The elegant jewelry boxes from Omet perfectly showcase our diamond collection. The hot stamping finish adds a premium touch that our customers love. Professional service from design to delivery."

Elena Rodriguez

Brand Manager, Diamond Elegance

"Outstanding cosmetics packaging solutions! Omet's laminating technology gives our skincare boxes the perfect premium finish. Their understanding of beauty industry requirements is impressive."

Jennifer Wang

Packaging Manager, Beauty Innovations

"Perfect shopping bags for our fashion retail chain! The die-cutting precision and handle strength are excellent. Omet's BSCI certification aligns perfectly with our sustainability goals."

David Thompson

Retail Operations Manager, Fashion Forward

"Robust packaging solutions for our tech products. Omet's advanced equipment ensures consistent quality across large orders. Their logistics support streamlined our global distribution process significantly."

Alex Kumar

Global Sourcing Manager, TechGlobal Inc.

Join thousands of satisfied customers who trust Omet for their packaging needs

Certifications

Our commitment to quality, sustainability, and ethical practices is backed by internationally recognized certifications.

FSC Certification

The Forest Stewardship Council certification ensures that products come from responsibly managed forests that provide environmental, social, and economic benefits.

-

Ensures paper comes from responsibly managed forests

-

Protects biodiversity and indigenous peoples' rights

-

Chain of custody verification throughout the supply chain

BSCI Certification

The Business Social Compliance Initiative certification verifies that our facilities maintain fair and ethical working conditions in accordance with international standards.

-

Ensures fair compensation and working hours

-

Prohibits discrimination and child/forced labor

-

Promotes occupational health and safety

Additional Quality Standards

Product Safety Testing

Our products undergo rigorous testing for harmful substances and comply with international safety standards including REACH and CPSIA requirements.

Environmental Management

Our facilities follow environmental management practices aligned with ISO 14001 standards, focusing on waste reduction and energy efficiency.

Quality Management

We implement comprehensive quality management systems that ensure consistent product quality and continuous improvement in our processes.

Frequently Asked Questions

Get answers to common questions about our custom paper box solutions

What types of custom paper boxes do you offer?

We manufacture a wide range of custom paper boxes including gift boxes, product packaging boxes, shipping boxes, jewelry boxes, cosmetic boxes, food packaging boxes, and electronic product boxes. All can be fully customized to your specifications.

What is your minimum order quantity (MOQ)?

Our standard MOQ is 500 pieces per design. However, we can accommodate smaller quantities for sample orders or specific requirements. Contact us to discuss your project needs and we'll find the best solution for you.

How long does production take?

Standard production time is 7-15 business days after design approval and deposit payment. Rush orders can be accommodated in 3-7 days with additional fees. Complex designs or special finishes may require additional time.

What printing options are available?

We offer full-color offset printing, digital printing, hot stamping (gold/silver foil), embossing, debossing, UV coating, and matte/gloss lamination. Our advanced equipment ensures high-quality finishes for any design requirement.

Do you provide design services?

Yes! Our experienced design team can create custom packaging designs from concept to completion. We offer free design consultation and can work with your existing artwork or create entirely new designs that enhance your brand value.

What materials do you use for paper boxes?

We use high-quality materials including corrugated cardboard, kraft paper, art paper, specialty papers, and eco-friendly recycled materials. All materials are FSC certified, ensuring sustainable and environmentally responsible packaging solutions.

Can I get samples before placing a large order?

Absolutely! We provide samples for quality evaluation. Existing samples are free, while custom samples have a small fee that's refundable with your first order. We recommend sampling to ensure complete satisfaction with materials and printing quality.

What are your payment terms?

We accept 30% deposit to start production and 70% balance before shipping. Payment methods include T/T bank transfer, L/C, and PayPal for smaller orders. We provide detailed invoices and can accommodate specific payment requirements for established clients.

Do you handle international shipping?

Yes, we export globally with comprehensive logistics support. We handle all export documentation, customs clearance, and can arrange shipping via sea freight, air freight, or express courier. Our experienced team ensures safe delivery worldwide.

What quality certifications do you have?

We are BSCI and FSC certified, ensuring ethical manufacturing practices and sustainable sourcing. Our facility follows strict quality control procedures with comprehensive testing protocols to guarantee consistent, high-quality packaging solutions for every order.

Still have questions about our custom paper box solutions?