Custom Wrapping Paper Manufacturer & Supplier in China

From concept to delivery - explore our comprehensive packaging paper solutions with detailed specifications, processes, and expert guidance | B2B

Complete Wrapping Paper Guide

On this page, you can explore comprehensive information about custom packaging paper solutions. Click on each directory item to read detailed content and fully understand our packaging paper offerings to help you customize the perfect solution for your needs.

Product Collection

More wrapping paper

MOQ

Minimum order quantities

Materials

Paper material options

Sizes

Available dimensions

Printing

Printing techniques

Crafting

Special processes

Packaging

Packaging methods

Cost Analysis

Pricing breakdown

Timeline

Production schedule

Common Pitfalls

Avoid mistakes

Why Us

Our advantages

Certificates

Quality certifications

FAQ

Common questions

Related Products

Other solutions

Ready to Start?

Get personalized consultation

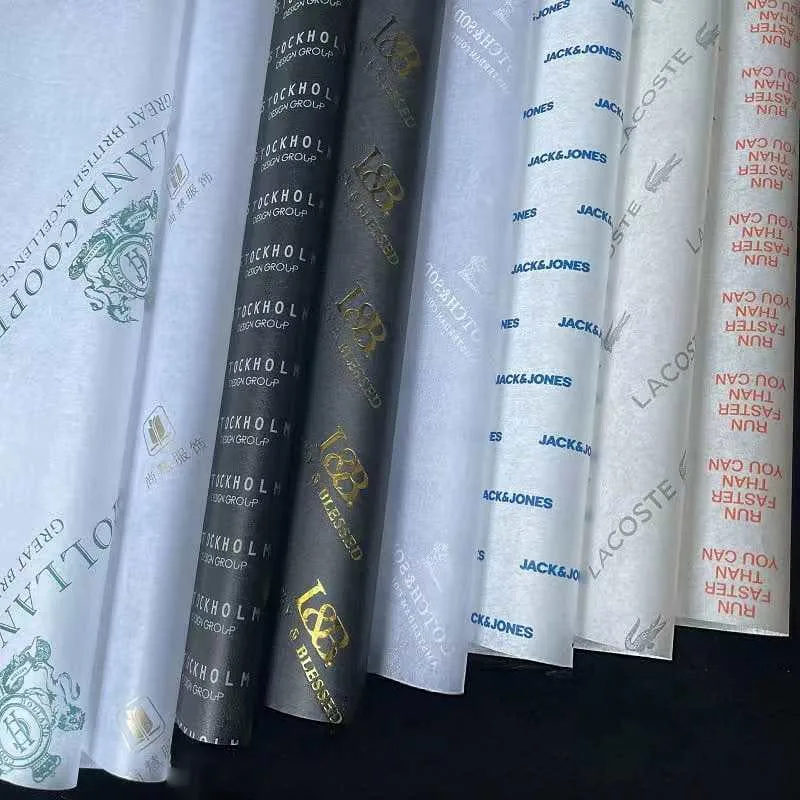

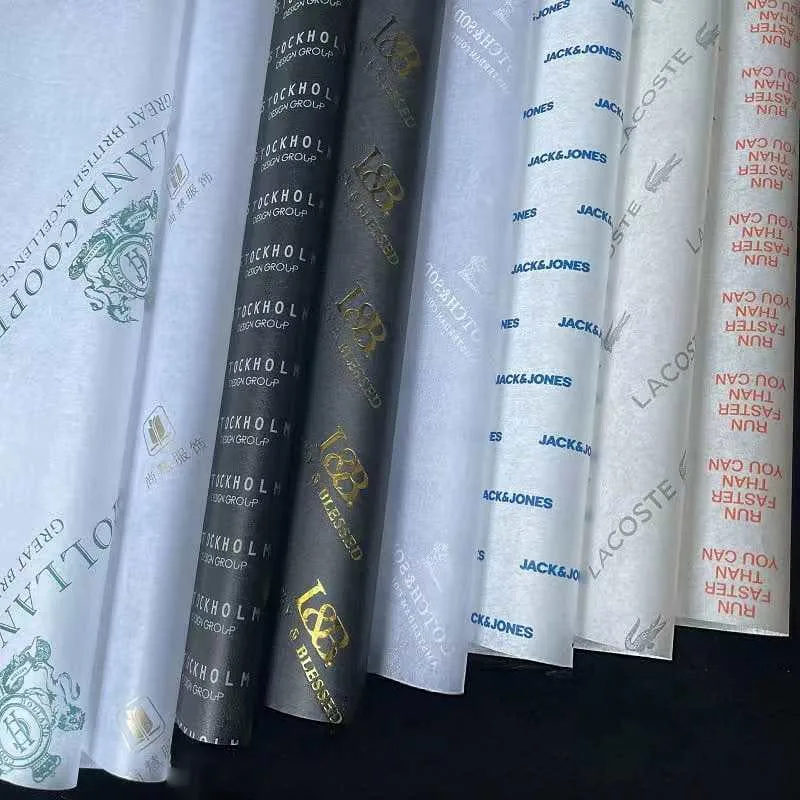

Wrapping Packaging Paper Collection

Explore custom gift wrapping paper, flower wrap, specialty films, and certified food-grade papers. OEM/ODM printing, sustainable options, and flexible roll/sheet formats for retail, gifting, and brand packaging.

Luxury Hot-Stamping Wrapping Paper

Premium 80–100gsm gift wrap with crisp hot-foil accents (gold/silver/rose gold). Ideal for boutiques and premium retail gifting. Supports custom sizes, CMYK/Pantone, and recyclable paper stocks.

Christmas Wrapping Paper (Retail & Wholesale)

Vibrant holiday designs on 80gsm art paper with UV printing for fade-resistant color. Available in rolls or sheets; perfect for seasonal promotions, online shops, and private-label packaging.

Birthday Kraft Wrapping Paper

Eco-friendly kraft gift wrap (70–90gsm) with playful birthday motifs. Strong tear resistance, soy-based inks, and fully recyclable—great for party stores and sustainable brands.

Valentine’s Day Wrapping Paper

Romantic heart and script patterns on 100gsm art paper with optional spot UV/embossing. Perfect for gift shops, jewelry packaging, and seasonal retail displays.

Kids Gift Wrapping Paper

Bright, playful prints on durable LWC/offset paper. Safe, low-odor inks. Custom cartoon themes and retail barcoding for supermarkets and party chains.

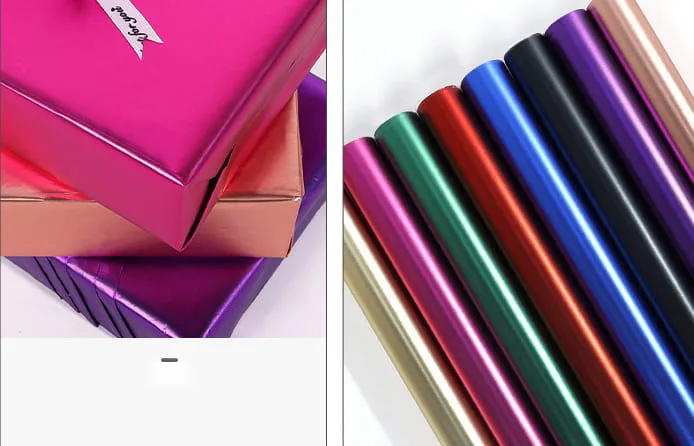

Metallic & Foil Wrapping Paper

Mirror and brushed metallic effects with hot-foil stamping. Premium look for weddings and luxury branding; supports custom logos, wraps, and belly bands.

Gift Wrapping Paper Rolls

Retail-ready roll formats (3–10m) with shrink wrap and hang tabs. Custom core sizes and UPC labeling—ideal for supermarkets and e-commerce bundles.

Gift Wrapping Paper Sheets

Pre-cut sheets for fast packing and subscription boxes. Smooth print surface, crisp folds, and MOQ-friendly custom artwork for brand campaigns.

Gift Wrapping Sets & Kits

Coordinated paper, tags, ribbons, and stickers in one kit. Private-label packaging with barcode and box design for retail displays and gift aisles.

Gift Wrapping Tissue Paper

Lightweight 17–22gsm tissue for box lining and retail packaging. Acid-free options, brand logo printing, and wide color library for premium unboxing.

Christmas Tissue Paper

Seasonal tissue with festive prints for hampers and gift boxes. Soft, bleed-resistant, and available in metallic ink highlights for holiday campaigns.

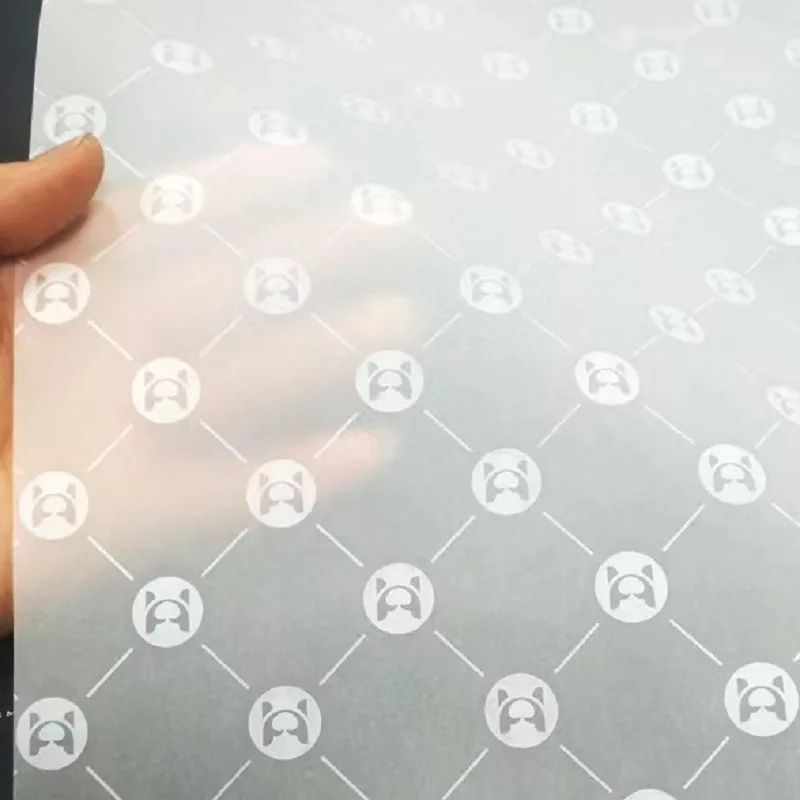

Custom Tissue Paper with Logo

Branded tissue with repeating step-and-repeat logos, ideal for boutiques and DTC brands. Low MOQs, crisp Pantone matches, and FSC-certified base paper available.

Transparent Wrapping Film

High-clarity 20μm film to showcase bouquets and gifts. Scratch-resistant, easy to fold, and printable—great for florists and event packaging.

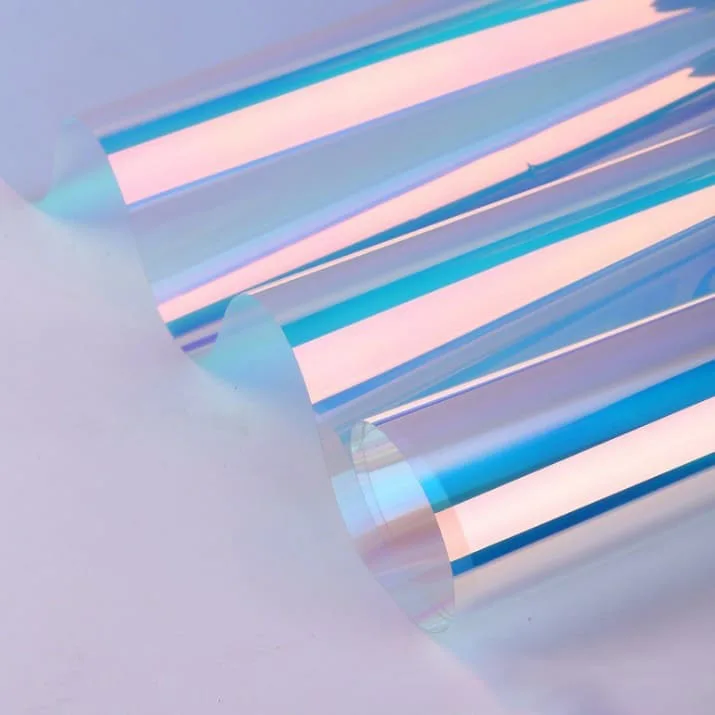

Holographic Wrapping Film

Eye-catching iridescent finish for bouquets and premium gifts. Strong crease memory and heat-sealable edges; supports custom widths and patterns.

Rainbow Effect Film

Soft rainbow sheen with premium transparency. Popular for florist wraps, product display sleeves, and gift basket packaging.

Waterproof Flower Wrapping Paper

Water-resistant 100gsm paper for fresh bouquets. Clean edges, rich colors, and excellent shape retention—ideal for daily florist work.

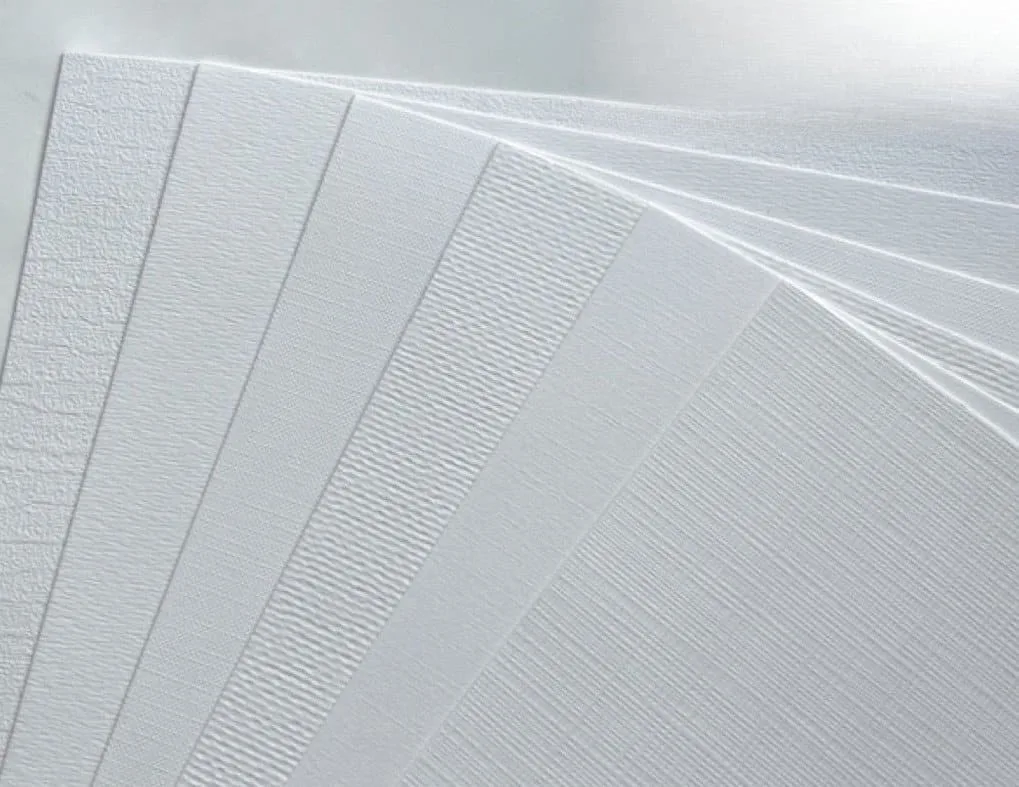

Textured Flower Paper

Elegant textured surface with fabric-like touch. Enhances bouquet presentation and premium gift sets; multiple colors and emboss patterns available.

Clear Cellophane for Flowers

Crystal-clear cello wrap for bouquets and gift baskets. Moisture resistance and high tensile strength keep arrangements neat during transport.

Food Wrapping Paper (Grease-Resistant)

FDA/EU compliant paper with food-safe inks and oil barrier. Ideal for bakeries, delis, and quick-serve brands. Custom logo printing and sheet/roll supply.

Deli & Sandwich Wrap

Moisture- and grease-resistant deli sheets for burgers, wraps, and fries. Breathable structure prevents sogginess; custom sizes and dispenser-box packing.

Bakery Wrapping Paper

Elegant bakery wraps with oil-resist coating for pastries and breads. Print your logo edge-to-edge; supplied flat or on rolls for fast service lines.

Minimum Order Quantities for Packaging Paper

Optimize your packaging operations with our recommended minimum order quantities (MOQs) for sheet and roll packaging paper. Designed for cost efficiency, production optimization, and shipping convenience.

Sheet Packaging Paper

Minimum order 3,000 sheets. Perfect for small to medium businesses needing custom printed sheets in standard sizes.

Sheets minimum order

Roll Packaging Paper

Minimum order 10,000 meters. Ideal for high-volume packaging operations and continuous production lines.

Meters minimum order

Cost Efficiency

Lower per-unit costs with our minimum order quantities, ensuring better value for your investment.

Production Optimization

MOQs are designed to optimize production efficiency while maintaining high-quality standards.

Shipping Efficiency

Minimum quantities ensure efficient shipping and logistics, reducing overall transportation costs.

Paper Materials for Packaging, Printing & Wrapping

Explore our collection of wholesale paper materials designed for packaging, gift wrapping, printing, and branding. From eco-friendly kraft to premium foiled finishes, our materials meet both sustainable and luxury packaging needs.

Custom Tissue Paper

Lightweight tissue paper packaging material perfect for gift wrapping, retail bags, and flower bouquets. Provides an elegant and protective finish.

Glazed Paper

Smooth glazed paper material designed for colorful printing, promotional wrapping, and retail packaging.

Custom Parchment Paper

Durable parchment paper safe for food wrapping, bakery packaging, and eco-friendly gift wrapping.

PE Laminated Paper for Packaging

Moisture-resistant PE coated paper widely used in food packaging, takeaway bags, and protective wrapping.

Light Weight Coated Paper (LWC)

Smooth LWC paper designed for magazine-quality printing, brochures, and colorful packaging.

Coated Art Paper (C2S)

Premium coated art paper with smooth finish, perfect for luxury packaging, brochures, and premium gift wrap.

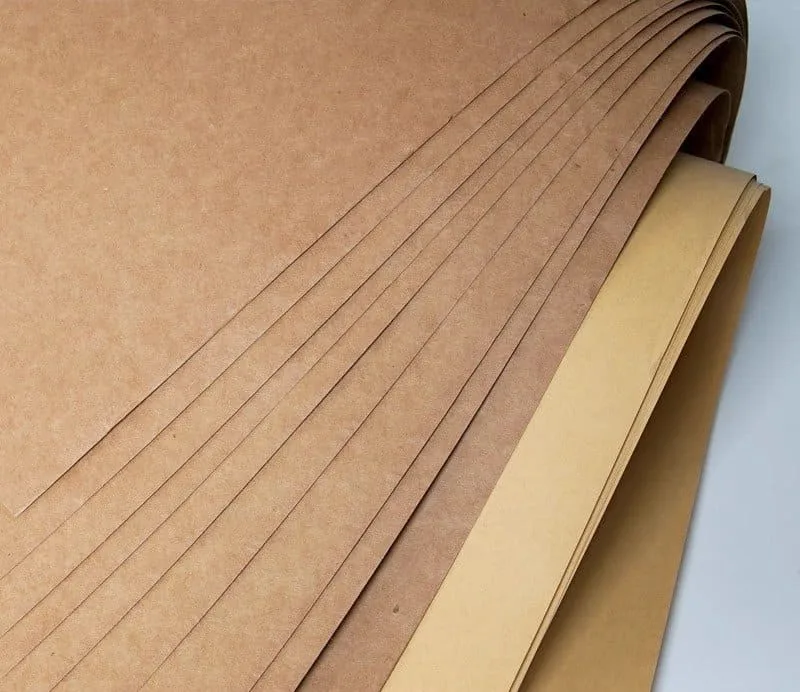

Brown & White Kraft Paper (Eco-Friendly)

Strong eco-friendly kraft paper perfect for sustainable packaging, paper bags, and natural branding.

Metallic Foiled Paper

Metallic foiled paper that adds elegance and shine to luxury gift wrapping, premium branding, and festive packaging.

Glitter Paper

Strong eco-friendly kraft paper perfect for sustainable packaging, paper bags, and natural branding.

Transparent Film

Clear transparent film material designed for product visibility, moisture protection, and flexible packaging.

Holographic Film

Stylish holographic film adds shine and uniqueness to premium gift packaging, cosmetics, and promotional wraps.

Specialty Textured Paper

Unique textured specialty paper designed for luxury branding, custom packaging, and creative wrapping.

Available Packaging Paper Sizes

Explore our standard and custom packaging paper sizes for sheets and rolls, perfect for gifts, retail, and industrial use.

Sheet Packaging Paper Sizes

Standard size perfect for gift wrapping, boutique packaging, and small to medium packaging projects.

Large format for bigger items, commercial packaging, and professional gift presentations.

Fully customized dimensions available to meet your unique packaging requirements.

Roll Packaging Paper Sizes

Compact roll size for moderate usage.

Extended length for increased efficiency.

Long roll for high-volume operations.

Maximum standard length for industrial applications.

Customized roll dimensions available for any specific packaging project.

Size Selection Guide for Packaging Paper

Gift Wrapping

50×70cm sheets for gift boxes, personal projects, boutique packaging.

Retail Packaging

70×100cm sheets for larger retail packaging and branding.

Industrial Use

Roll formats ideal for continuous production lines and high-volume operations.

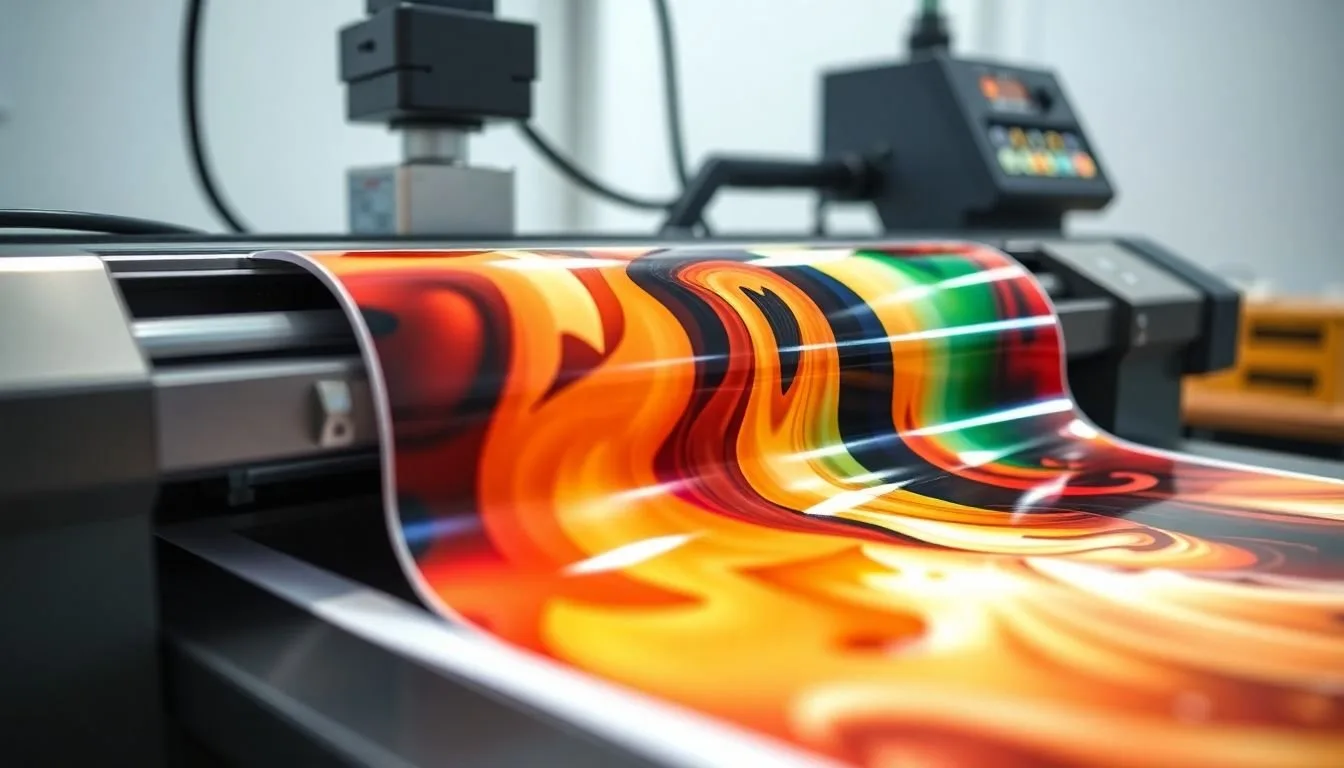

Printing Options

Explore different printing technologies to find the best fit for your packaging needs.

Four Color Printing (CMYK)

Standard four-color process printing using Cyan, Magenta, Yellow, and Black inks. Perfect for full-color designs and photographic images.

Best For:

- • Full-color photographs

- • Complex multicolor designs

- • Cost-effective color printing

- • Large volume orders

Spot Color Printing

Precise color matching using Pantone system. Ensures consistent brand colors and effects that cannot be achieved with CMYK.

Best For:

- • Brand color consistency

- • Metallic and fluorescent colors

- • Simple designs with few colors

- • Premium packaging

UV Printing

Advanced UV-cured ink printing technology that provides superior durability, vibrant colors, and instant drying for enhanced print quality.

Best For:

- • High-end luxury packaging

- • Outdoor applications

- • Enhanced durability needs

- • Special effects and textures

Printing Comparison Guide

| Printing Type | Color Range | Cost | Durability | Best Application |

|---|---|---|---|---|

| Four Color (CMYK) | Full spectrum | Most economical | Standard | General packaging |

| Spot Color | Precise matching | Moderate | Good | Brand consistency |

| UV Printing | Enhanced vibrancy | Premium | Excellent | Luxury packaging |

Premium Paper Crafting & Finishing Options for Packaging

Explore our range of sustainable, customizable, and eco-friendly paper finishing options that elevate your packaging design with texture, shine, and durability.

Hot Stamping Metallic Foil

Add luxurious metallic foil stamping to your packaging with gold, silver, or custom colors for premium branding.

- • Luxurious metallic finish

- • Brand enhancement

- • Premium retail packaging

Embossing & Debossing

Create elegant raised or recessed textures with embossing and debossing, adding tactile depth to packaging designs.

- • Tactile surface

- • Dimensional brand impact

- • Premium presentation

Glitter Packaging Effect

Sparkling glitter paper finish adds festive shine and eye-catching appeal for gift wraps and holiday packaging.

- • Festive occasions

- • Eye-catching sparkle

- • Holiday gift wraps

Foaming Raised Effect

Dimensional foaming effect delivers a soft touch feel and premium packaging texture with cushioned surface.

- • Soft tactile feel

- • Unique texture

- • Dimensional design

Velvet Flocking Finish

Add elegance with a soft velvet flocking finish, delivering a luxurious and tactile surface on premium packaging.

- • Velvet-like feel

- • Luxury branding

- • Premium packaging

Holographic Paper Effect

Stunning holographic rainbow paper effect changes colors at every angle, perfect for modern and trendy packaging.

- • Color-changing design

- • Eye-catching finish

- • Trendy appeal

Waterproof Coating

Protective waterproof paper coating ensures durability and resistance to moisture for reliable packaging use.

- • Water-resistant

- • Long-lasting durability

- • Outdoor friendly

Oil Resistant Coating

Grease-proof oil resistant paper coating is perfect for eco-friendly food packaging, bakery wraps, and takeout boxes.

- • Food-safe

- • Grease-proof

- • Eco-friendly option

Professional Packaging Methods for

Custom Wrapping Paper Manufacturing

Discover our comprehensive range of packaging solutions designed for custom tissue paper, gift wrapping paper, and premium packaging materials. From retail-ready displays to bulk wholesale packaging, we offer vavious packaging methods that protect your products while enhancing brand presentation.

Flat Sheet Premium OPP Bag Packaging

Individual tissue paper sheets packaged flat in crystal-clear OPP bags, ensuring zero creases and maintaining pristine condition for luxury gift wrapping and retail presentation.

Key Benefits:

- Zero fold marks

- Professional display

- Moisture protection

- Easy handling

Space-Saving Folded Sheet OPP Packaging

Expertly folded tissue paper sheets in protective OPP bags, optimized for compact storage and cost-effective shipping while maintaining product integrity for wholesale distribution.

Key Benefits:

- 50% space saving

- Lower shipping costs

- Organized storage

- Bulk friendly

Retail-Ready Single Roll Packaging

Individual gift wrapping paper rolls with premium protective packaging, designed for retail environments with professional branding and point-of-sale appeal.

Key Benefits:

- Retail display ready

- Brand enhancement

- Individual protection

- Easy handling

Bulk Multi-Roll Wholesale Packaging

Multiple wrapping paper rolls securely bundled for wholesale distribution and bulk orders, featuring cost-effective packaging solutions with protective materials for safe transportation.

Key Benefits:

- Bulk order efficiency

- Reduced costs

- Secure bundling

- Wholesale ready

Complete Gift Wrapping Ensemble Kits

Comprehensive gift wrapping sets combining custom tissue paper, wrapping paper, ribbons, and accessories in beautifully presented packages for complete gifting solutions.

Key Benefits:

- Complete solutions

- Gift set appeal

- Value addition

- Variety package

Premium Display Box Retail Packaging

Luxury display boxes engineered for retail environments, featuring premium materials and sophisticated design to showcase custom wrapping paper with maximum visual impact and brand presence.

Key Benefits:

- Premium display

- Brand enhancement

- Customer appeal

- Retail optimization

Ready to Choose Your Perfect Packaging Solution?

Our packaging experts are here to help you select the ideal packaging method for your custom wrapping paper needs. From eco-friendly options to premium retail displays, we'll ensure your products arrive safely and look spectacular.

Comprehensive Packaging Cost Analysis & Pricing Breakdown

Discover how custom packaging paper cost analysis works, including product pricing factors, shipping cost optimization, and additional fee breakdowns—helping you plan smarter and reduce overall expenses.

Key Product Pricing Factors

Understanding the main elements of custom packaging pricing helps you evaluate costs more accurately and optimize your budget effectively.

Quantity Requirements

- • Order volume directly impacts unit cost

- • Bulk discounts for higher quantities

- • MOQ considerations for production

Size Specifications

- • Standard vs. custom dimensions

- • Material usage efficiency

- • Impact on shipping weight & cost

Material Selection

- • Paper grade and thickness

- • Premium eco-friendly options

- • Direct impact on durability & price

Crafting Processes

- • Printing complexity & colors

- • Finishing effects (lamination, embossing)

- • Special quality enhancement features

Additional Cost Considerations

Packaging Requirements

Premium packaging such as display boxes or sets may raise costs but increase product value and customer perception.

Setup & Tooling Costs

Custom designs often require setup fees (printing plates, cutting dies). These one-time costs are spread across bulk orders.

Shipping Cost Analysis

Costs vary by destination, urgency, and volume. Our team recommends the most efficient option for your budget.

Other Fees Breakdown

Documentation Fees

Export documents & certifications

Quality Inspection

Third-party assurance services

Insurance Coverage

Cargo protection during transit

Banking Charges

International payment fees

Production Timeline – Custom Packaging & Printing Lead Time

Explore our step-by-step production timeline for custom packaging boxes and printing. From design approval to final shipping, our streamlined process ensures high-quality results delivered on time.

Pre-production Preparation – Custom Packaging Setup

1-3 Days

This phase includes design review, material sourcing, and production planning for custom packaging and printing. Ensures all specifications are confirmed before production begins.

Design Confirmation

Final artwork approval

Material Sourcing

Raw material preparation

Production Planning

Optimized scheduling

Sample Production – Custom Printed Box Prototypes

7-10 Days

We create sample prototypes of custom packaging boxes to verify quality, durability, and print accuracy before mass production.

Sample Creation

Physical prototype production

Quality Testing

Material and print verification

Payment Processing & Order Confirmation

1-3 Days

Once deposit payment is processed, mass production of your custom packaging and printing order begins immediately.

Mass Production – Printing & Packaging Lead Time

25-35 Days

Full-scale production including printing, finishing, quality control, and packaging. Ensures consistent results across large orders.

Material Prep

5-7 days

Printing

10-15 days

Finishing & QC

5-8 days

Packaging

3-5 days

Shipping & Delivery – Global Custom Packaging Orders

Varies by Method

Sea Freight

30-55 Days

Best for bulk orders

Air Freight

10-15 Days

Balanced cost & speed

Express Courier

7-10 Days

Fastest option

Common Pitfalls in Custom Packaging Paper: Avoid Mistakes & Improve Quality

Inadequate Color Specification

Not providing Pantone color codes or RGB values leads to color mismatches in custom packaging paper.

Solution:

Always specify exact Pantone colors or provide physical color samples for accurate matching.

Low Resolution Artwork

Submitting low-resolution images (below 300 DPI) results in blurry, pixelated prints on custom packaging.

Solution:

Provide vector files or high-resolution images (300 DPI minimum) in CMYK color mode.

Incorrect Size Calculations

Miscalculating dimensions leads to paper that doesn't fit intended products or packaging requirements.

Solution:

Double-check measurements and consider bleed areas. Request samples to verify sizing.

Unrealistic Timeline Expectations

Expecting immediate production without considering design, sampling, and manufacturing time requirements.

Solution:

Plan ahead and understand the complete production timeline including sampling phases.

Wrong Material Selection

Choosing inappropriate paper weight or type for the intended application affects durability and appearance.

Solution:

Consult with our material experts to select the optimal paper grade for your specific use case.

Ignoring MOQ Requirements

Underestimating minimum order quantities leads to higher per-unit costs and production inefficiencies.

Solution:

Plan orders to meet MOQ thresholds for better pricing and consider future needs.

Skipping Sample Approval

Proceeding to mass production without proper sample approval can result in costly reprints and delays.

Solution:

Always request and thoroughly review physical samples before approving mass production.

Inadequate Shipping Planning

Not considering shipping methods, costs, and delivery timeframes in project planning causes unexpected delays.

Solution:

Discuss shipping options early and factor delivery time into your project schedule.

Avoid These Pitfalls with Expert Guidance

Our experienced team helps you navigate the complexities of custom packaging paper production, ensuring smooth project execution from start to finish.

Why Choose Us for Wrpping Packaging Solutions

With over a decade of experience in custom wrapping paper manufacturing and sustainable packaging solutions, we provide high-quality, fully customizable products with global shipping and exceptional customer support.

10+ Years Experience

Extensive expertise in custom packaging paper production, delivering consistent quality worldwide.

Quality & Certified

BSCI & FSC certified eco-friendly packaging ensuring ethical production and sustainable sourcing.

Full Customization

Tailor every aspect of custom paper bags and packaging, from materials to finishing details.

Global Shipping

Reliable worldwide shipping for custom packaging orders to any destination with multiple logistics options.

24/7 Customer Support

Our support team is available anytime for assistance with orders, technical guidance, and inquiries.

Competitive Pricing

Factory-direct pricing with transparent costs, giving the best value without sacrificing packaging quality.

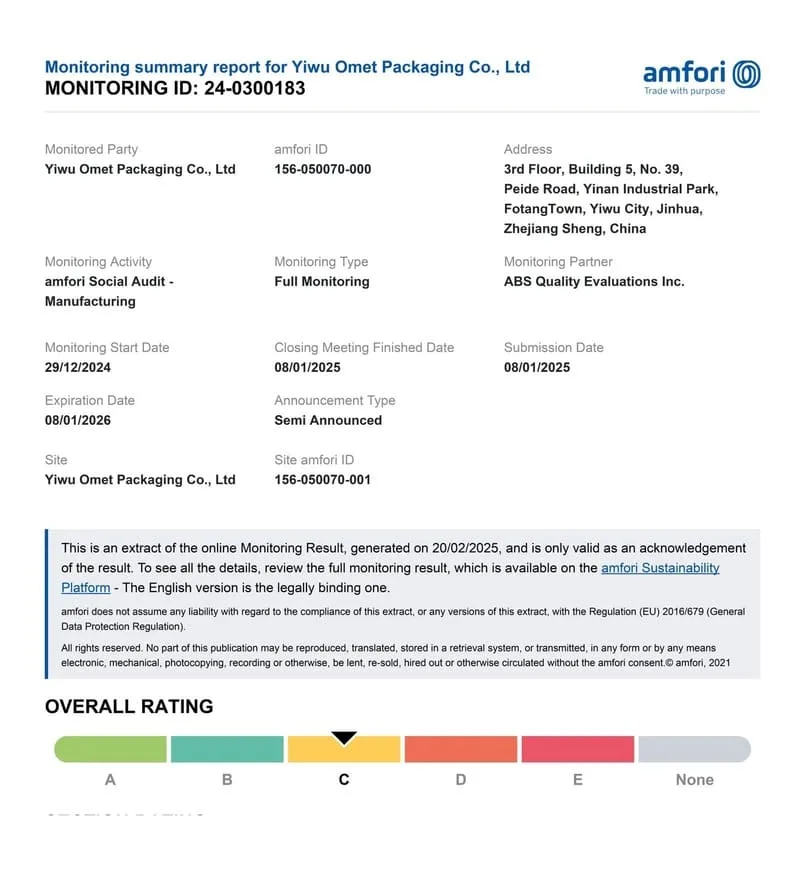

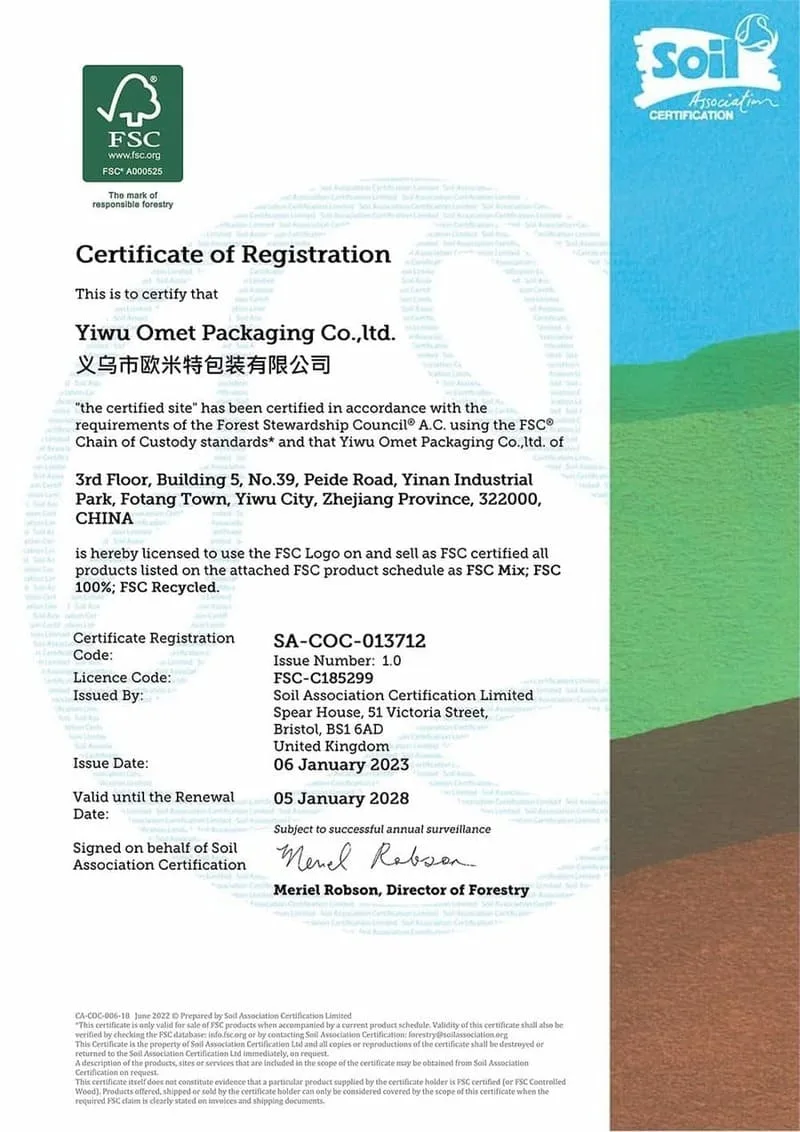

Quality Certificates for Sustainable Packaging

Omet Packaging holds BSCI and FSC certifications ensuring our custom wrapping paper manufacturing meets international standards for ethical production, environmental sustainability, and high-quality packaging solutions.

BSCI Certification

Business Social Compliance Initiative certification ensures our custom packaging production follows the highest social responsibility and ethical standards.

- Ethical labor practices

- Safe working conditions

- Environmental responsibility

- Fair employment standards

FSC Certification

Forest Stewardship Council certification guarantees our paper materials are sourced from responsibly managed forests, promoting sustainable packaging and environmental protection.

- Sustainable forest management

- Biodiversity conservation

- Community benefits

- Chain of custody tracking

Our Commitment to Quality, Sustainability & Ethical Packaging

Environmental Responsibility

Sustainable practices and eco-friendly materials in all custom paper bag production.

Social Responsibility

Fair labor practices and positive contribution to our local communities and workforce.

Quality Assurance

Maintaining top custom packaging quality standards through certified processes and continuous improvement.

Frequently Asked Questions About Custom Wrapping Paper

Explore our custom wrapping paper FAQs and learn how Omet Packaging ensures high-quality printing services, eco-friendly materials, and expert custom paper bag design for your brand.

1. What file formats are accepted for custom wrapping paper designs? ▼

We accept AI, EPS, PDF, PSD, and high-resolution JPG/PNG files. Vector formats (AI, EPS) are preferred for the best print quality.

2. Can you match specific brand colors on wrapping paper? ▼

We use Pantone matching. Provide color codes or samples and we ensure accurate color reproduction.

3. Do you offer samples before bulk production? ▼

Yes, samples take 7–10 days to verify material, print, and finishing quality before mass production.

4. What are your payment terms for custom wrapping paper orders? ▼

30–50% deposit to start production, balance before shipping. Payment via T/T, L/C, PayPal, etc.

5. Can you accommodate rush orders for wrapping paper? ▼

Expedited production available depending on capacity. Rush orders may incur extra fees.

6. Do you provide design consultation for custom wrapping paper? ▼

Our technical team optimizes artwork, color management, and print-ready files for your custom wrapping paper.

7. What quality control measures do you have? ▼

QC includes material inspection, color verification, print checks, and final packaging inspection.

8. Can you print sustainable and eco-friendly wrapping paper? ▼

Yes, we use FSC-certified paper and eco-friendly inks for environmentally responsible products.

9. Do you ship custom wrapping paper internationally? ▼

Yes, worldwide shipping via sea, air, or express courier. All necessary export documentation is provided.

10. Can you handle large-volume orders of wrapping paper? ▼

Full production capacity to manage bulk orders while maintaining quality and timely delivery.