Your Vision, Perfectly Food Packaged.

We're more than a supplier—we're your expert food packaging partner. Navigate every step of the food packaging process with our complete guide and dedicated support.

- Comprehensive Material & Finishing Options

- Clear Cost Analysis & Timeline Estimation

- Expert Guidance to Avoid Common Pitfalls

- Wide Range of Custom Products for Any Need

Your Ultimate Food Packaging Resource Hub

Navigate through our comprehensive food packaging guide. Each section provides detailed insights to help you make informed decisions and create packaging solutions that perfectly match your business needs.

Custom Products

Explore our customizable solutions

Sizes & Application

Dimensions and suitable products

Material Selection

Premium materials guide

Craft Selection

Premium finishing techniques

Printing Options

Various printing techniques

MOQ & Cost Analysis

Detailed pricing breakdown

Timeline Estimation

Production schedules

Common Pitfalls

Avoid packaging mistakes

Why Choose Us

Our competitive advantages

Customer Reviews

What clients say about us

FAQ

Frequently asked questions

Related Packaging

Know more about products

Ready to create exceptional food packaging? Let's get started!

Custom Food Packaging That Sells Your Story

From artisan chocolates to fresh pizza, we craft premium packaging that protects your products and amplifies your brand. Food-safe materials, stunning custom printing, and retail-ready finishes that turn every package into a marketing moment.

Premium Chocolate Boxes

Luxury rigid or folding cartons with custom inserts, foil, and embossing—food-safe finishes that elevate gifting.

Chocolate Boxes with Ribbon

Ribbon-tied flip-top or drawer styles—perfect for artisanal brands and boutique gifting.

Magnetic Closure Chocolate Boxes

Rigid magnet-lid boxes with premium trays—ideal for luxury collections and corporate gifts.

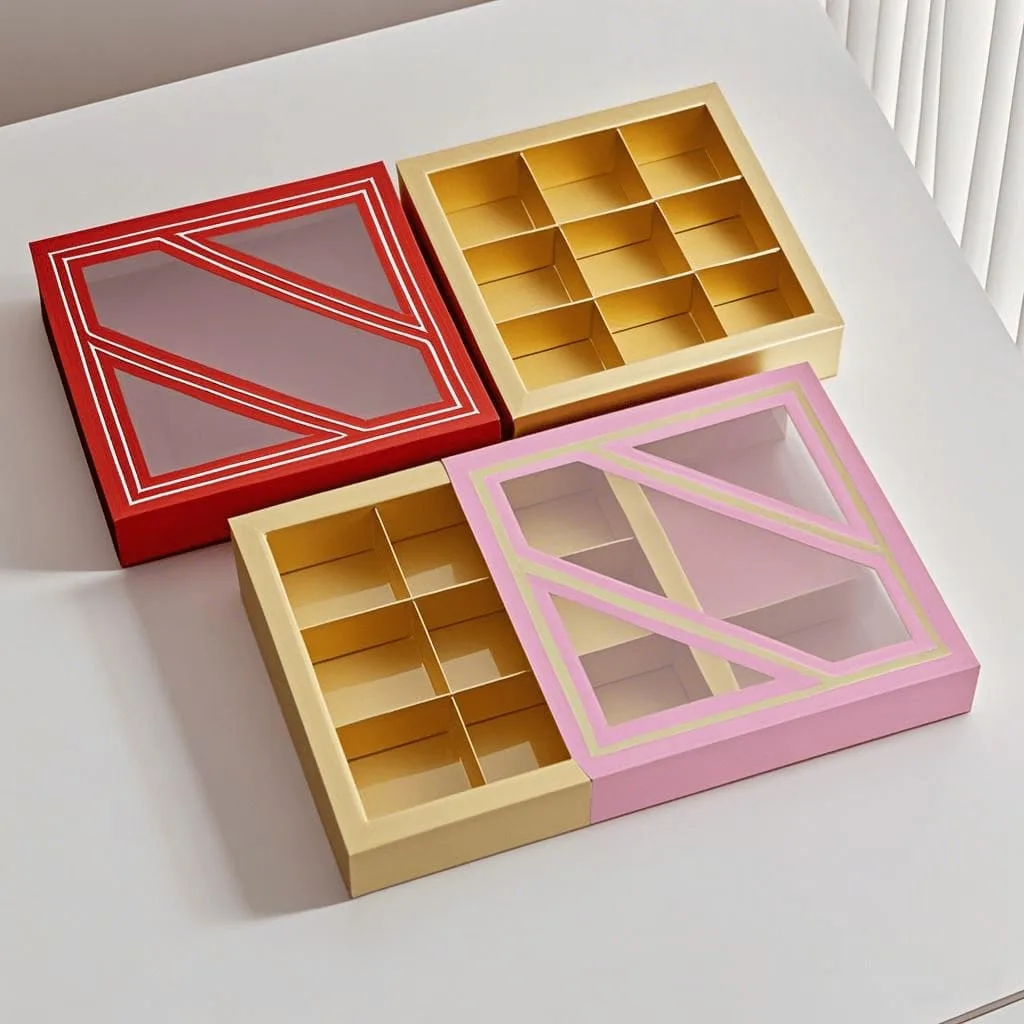

Chocolate Drawer Boxes with Window

Pull‑out trays with PET windows showcase assortments; custom cavities keep pieces pristine.

Advent Calendar Chocolate Boxes

12/24‑day calendars with die‑cut doors, seasonal artwork, and retail‑ready construction.

Window Cake Boxes

Clear PET windows, sturdy locks, and food-safe liners—display beautifully, travel safely.

Kraft Cake Boxes

Recyclable kraft board with a natural look—sturdy, grease-resistant, and FSC-ready.

Cupcake Boxes

Inserts for 1/4/6/12 cupcakes, vent holes, and optional handles—perfect for events and retail.

Candy Boxes with Handle

Gift-ready boxes with multi-section options—food-safe, portable, and brandable.

Candy Pillow Boxes

Elegant pillow packs for favors and sweets—quick to assemble, fully recyclable.

Complete Baking Packaging Sets

All‑in‑one kits—boxes, bags, liners, labels—cohesive branding from oven to storefront.

Baking Packaging Set

Cupcake supplies and decorating kits—custom trays, inserts, and sleeves matched to your SKUs.

Donut Packaging Sets

Coordinated boxes, bags, and labels that keep donuts fresh and neatly presented.

Premium Donut Boxes

Rigid or folding board with nice design and carry bag options—made for gourmet presentations.

Macaron Packaging Boxes

6/12/24‑cavity trays with clear lids or sleeves—vibrant printing and gift‑ready options.

Luxury Macaron Boxes

Ribbon closures, foil, and emboss/deboss—rigid setup boxes that delight on unboxing.

Fast Food Packaging

Burger clamshells, fry sleeves, and sauce cups—grease‑proof and delivery‑ready.

Coffee Carry Packaging Set

2/4‑cup carriers, sleeves, lids, and bags—sturdy, spill‑safe, and easy to brand.

Aluminum Foil-Lined Pizza Boxes

Heat‑retentive, grease‑proof interiors keep pies hot and crisp for longer deliveries.

Custom Pizza Boxes

Your logo, sizes 7–18", venting options, E‑flute/C‑flute, and food‑safe inks for bold branding.

Takeaway Packaging Kits

Coordinated boxes, cups, bags, and wraps—consistent branding across your entire menu.

Food Wrapping Papers

Greaseproof deli sheets and burger wraps—crisp print with soy‑based, food‑safe inks.

Branded Food Carry Paper Bags

Strong twisted or flat handles, custom sizes, and recyclable kraft or white stocks.

Kraft Paper Carry Bags

Eco‑friendly takeaway bags with reinforced bottoms—built to carry heavier orders with ease.

Trusted by 1000+ businesses worldwide

Perfect Dimensions for Every Food Product

Choose from our comprehensive range of standard food packaging sizes or create custom dimensions that perfectly fit your products. Every box is engineered for optimal protection, efficient storage, and stunning presentation.

Small Format

Perfect for Individual Treats

Medium Format

Ideal for Sweet Collections

Large Format

Perfect for Main Events

Extra Large

Built for Big Occasions

Custom Dimensions Available

Need something specific? We create bespoke packaging solutions tailored to your exact product requirements and brand vision.

Any Dimensions

Custom length, width, height to match your exact needs

Unique Shapes

Square, rectangular, hexagonal, or completely custom forms

Smart Storage

Stackable, nestable, and collapsible designs for efficiency

Food Safe

FDA compliant materials and food-grade coatings

Premium Gift Sets

Combine small and medium boxes for elegant product presentations and varied gift experiences

Restaurant Solutions

Complete packaging suite for takeaway, delivery, and dine-in presentations across your menu

Corporate Packages

Consistent sizing and branding across all corporate gifting and business presentation needs

Precision engineering for perfect fit every time

Food-Safe Packaging Materials Built for Performance & Sustainability

Every material in our collection meets the highest food safety standards while delivering exceptional durability and visual appeal. From eco-friendly kraft to luxury rigid boards, find the perfect substrate that matches your brand values and product requirements.

Find Your Perfect Material Match

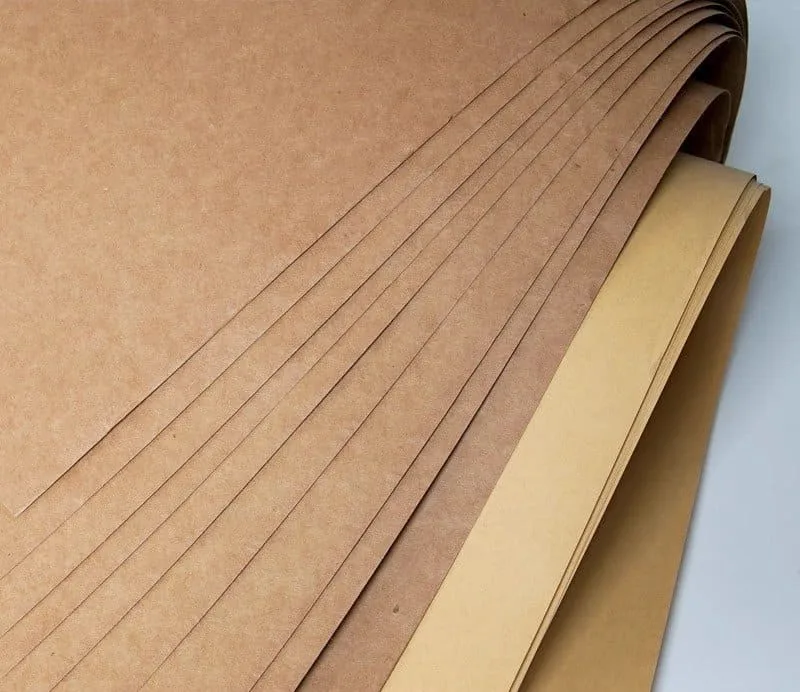

Natural Kraft Cardboard

The ultimate eco-friendly packaging solution that doesn't compromise on quality. Perfect for brands that want to showcase their environmental commitment while maintaining professional presentation standards.

Premium Coated

Superior print quality for vibrant branding and professional presentation.

Heavy-Duty Corrugated

Maximum strength for shipping, pizza boxes, and bulk packaging needs.

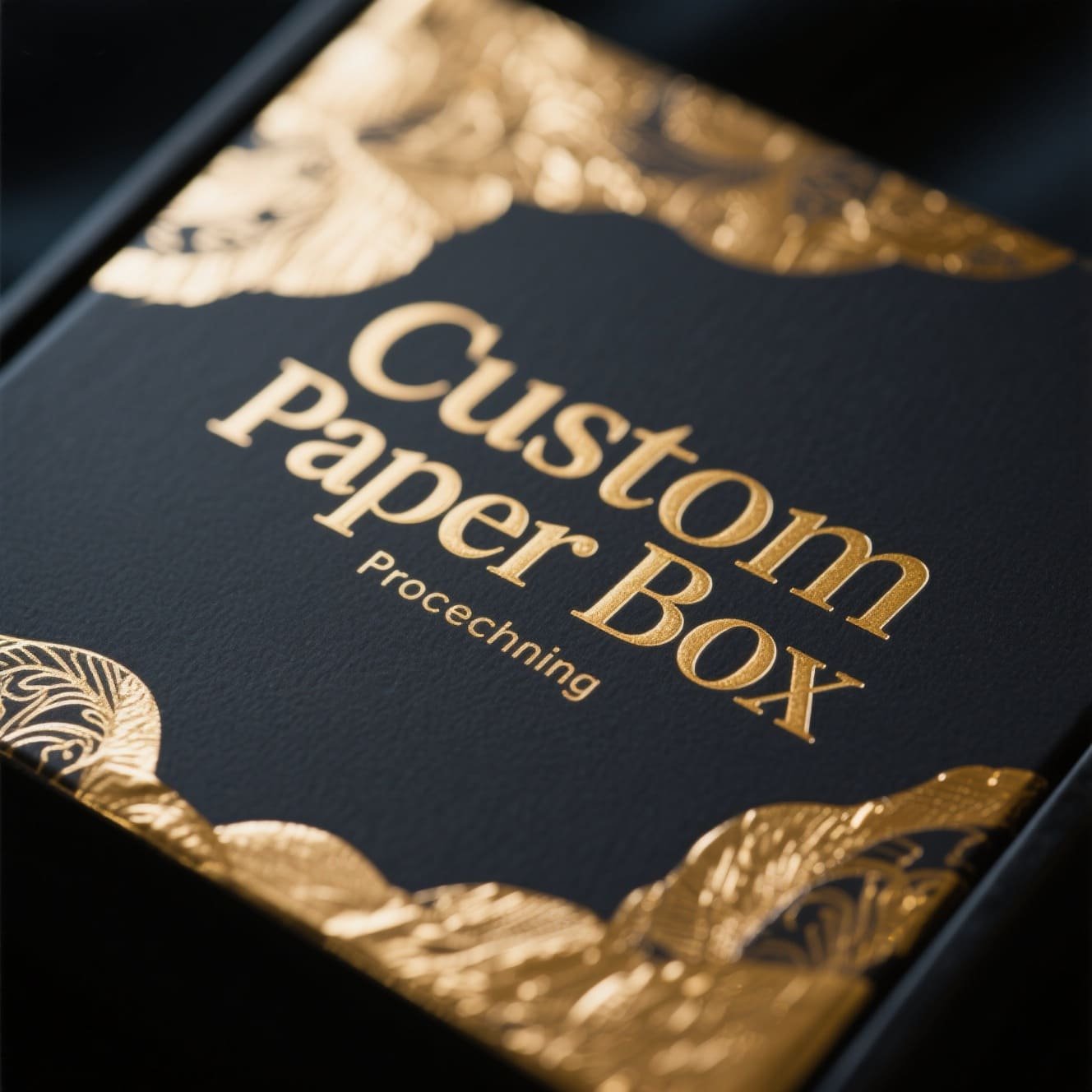

Luxury Rigid Paperboard

When your brand demands the absolute best, this premium material delivers unmatched sophistication. Perfect for luxury chocolate boxes, high-end gift packaging, and products that define excellence.

Quick Material Comparison

Compare key characteristics at a glance

Kraft Cardboard

Coated Cardboard

Corrugated Board

Rigid Paperboard

All materials certified for food contact and safety

Luxury Food Packaging Finishes Elevate Your Brand with Premium Touches

Transform ordinary packaging into extraordinary brand experiences. Our premium finishing techniques combine visual impact with tactile luxury, creating memorable unboxing moments that strengthen brand loyalty and justify premium pricing.

Find Your Perfect Finish

Choose based on your brand goals and budget

Hot Stamping Foil

Heat-pressed metallic foil creates brilliant, scratch-resistant finishes that catch the light beautifully. The ultimate choice for luxury brands wanting to make an unforgettable first impression.

Cold Foil Stamping

No-heat application enables complex patterns and multi-color effects with exceptional detail precision.

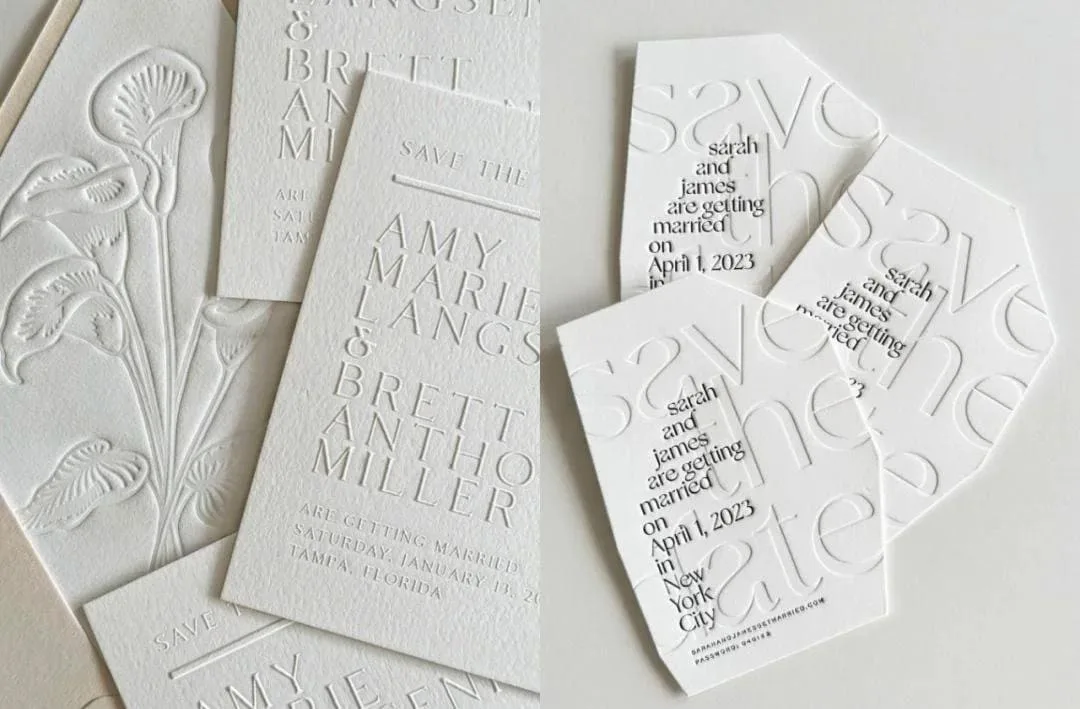

Embossing & Debossing

Creates dimensional texture through raised or recessed areas for sophisticated tactile appeal.

Soft-Touch Coating

Velvet-like rubber coating creates an irresistible tactile experience that customers can't help but touch. This premium finish transforms ordinary packaging into a sensory delight.

Spot UV Coating

Selective glossy UV varnish creates striking contrast against matte surfaces for sophisticated luxury enhancement.

Oil Resistant Coating

Advanced barrier coating prevents oil and grease penetration, keeping food packaging clean and professional.

Custom Combinations

Multiple techniques

Custom Combinations

Combine multiple finishing techniques for maximum impact. Create truly unique packaging that stands out from competitors.

Finish Performance Comparison

Quick reference guide to help you choose the perfect finishing technique

Hot Stamping

Soft-Touch

Spot UV

All finishing techniques food-safe and premium quality certified

Food Packaging Printing Options Color‑perfect. Durable. Retail‑ready.

Choose the right printing technique for your packaging goals. From photo‑real CMYK to Pantone‑accurate spot colors and ultra‑durable UV, we deliver crisp color, consistent results, and premium finish.

Four Color Printing (CMYK)

- Full‑spectrum color for photos and gradients

- Consistent, cost‑effective production

- Ideal for multi‑color branding

Standard four‑process inks (cyan, magenta, yellow, black) deliver vivid imagery with balanced tonal range.

Spot Color Printing (Pantone)

- Exact brand color with Pantone inks

- Ultra‑clean solids and linework

- Perfect for logos and corporate palettes

Dedicated spot inks ensure repeatable, consistent hues across runs and substrates.

UV Printing

- Instant UV‑cured inks, fast turnaround

- High scratch and scuff resistance

- Deep, vibrant color density

A premium process for long‑lasting, vibrant prints—ideal for high‑touch packaging and display.

Screen Printing

- Thick ink laydown for bold, opaque color

- Metallics, textures, and specialty effects

- Hand‑crafted aesthetic

A classic technique that excels at tactile finishes and statement graphics on select substrates.

Printing Technique Comparison

CMYK

Spot Color

UV

Screen

Packaging Cost & MOQ Guide Understand pricing drivers. Optimize your unit cost.

Your final unit price depends on quantity (MOQ), size, materials, printing, finishing, and shipping. Use this guide to plan budgets, choose the right MOQ, and discover proven cost‑saving strategies.

Minimum Order Quantity (MOQ)

The more you order, the lower your unit cost. Typical MOQs vary by product, print method, and finishing. Below are common breakpoints for food packaging.

Unit Cost Trend (Indicative)

Note: Actual pricing depends on size, materials, printing, finishing, and logistics.

- MOQ starts at 500 pcs per design/size; unit price will be higher

- 3,000 pcs provide a more balanced unit price

- 5,000–10,000 pcs unlock the most competitive pricing

- Volume discounts apply for larger quantities

Product Pricing Factors

Share key specs to get accurate unit pricing for your packaging.

- Quantity (by design/size)

- Dimensions (L × W × H)

- Material (kraft, coated, corrugated, rigid)

- Printing (CMYK, Pantone, UV, screen)

- Finishing (foil, emboss, spot UV, soft‑touch)

- Packing method (flat, pre‑assembled)

Shipping Costs

Choose the best balance between time and budget.

Additional Costs

May apply based on destination and requirements.

- Customs duties & local taxes

- Documentation & handling fees

- Cargo insurance (recommended)

- Storage (if applicable)

- Rush order surcharges

Cost Optimization Strategies

Immediate Savings

- • Consolidate SKUs and order larger batches

- • Prefer standard sizes over custom dimensions

- • Bundle products into one shipment

- • Schedule production in off‑peak seasons

Long‑Term Value

- • Invest in materials that elevate brand perception

- • Consider reusable or modular designs

- • Build supplier partnerships for better tiers

- • Optimize packaging for freight efficiency

Production Timeline Overview

Track your order journey from concept to delivery with our streamlined process

Pre-Production

Design confirmation, material prep & planning

Sample Creation

Physical sample & quality testing

Payment

Secure deposit processing

Manufacturing

Full production & quality control

Shipping

Flexible delivery options

Choose Your Shipping Speed

Sea Freight

30-55 Days

Most economical option

Air Freight

10-15 Days

Balanced speed & cost

Express Courier

7-10 Days

Fastest delivery

Total Production Time: 29-46 days + shipping

Get started today to receive your order sooner

Avoid These Critical Mistakes

Transform your packaging project from potential disaster to guaranteed success. Learn from industry experts who've seen every mistake in the book.

Design & Specification Mistakes

Inadequate Size Planning

Choosing wrong dimensions that don't properly fit your products or create excessive waste space.

Solution: Always test with actual products before finalizing dimensions.

Poor Color Reproduction

Not accounting for color differences between screen display and actual printing results.

Solution: Always request physical color samples and use Pantone color matching.

Ignoring Food Safety Requirements

Using materials or inks that aren't food-safe or compliant with local regulations.

Solution: Verify all materials meet FDA and local food safety standards.

Production & Quality Issues

Skipping Sample Phase

Proceeding directly to bulk production without proper sample testing and approval.

Solution: Always invest in samples to catch issues before mass production.

Insufficient Quality Control

Not implementing proper quality checks during production, leading to defective products.

Solution: Establish clear quality standards and inspection protocols.

Unrealistic Timeline Expectations

Underestimating production time and rushing the process, compromising quality.

Solution: Plan 2-3 months ahead and allow buffer time for unexpected delays.

Cost & Budget Pitfalls

Hidden Cost Surprises

Not accounting for setup fees, shipping costs, customs duties, and other additional expenses.

Solution: Request comprehensive quotes including all potential costs.

Ordering Wrong Quantities

Ordering too few units (high unit cost) or too many (cash flow and storage issues).

Solution: Analyze your usage patterns and storage capacity carefully.

Choosing Cheapest Option

Prioritizing low cost over quality, leading to poor brand perception and customer complaints.

Solution: Balance cost with quality to maintain brand reputation and customer satisfaction.

Logistics & Shipping Problems

Inadequate Packaging Protection

Insufficient protective packaging leading to damage during transit and storage.

Solution: Invest in proper protective packaging and conduct drop tests.

Poor Shipping Method Selection

Choosing inappropriate shipping methods that don't match timeline or budget requirements.

Solution: Evaluate all shipping options and choose based on urgency and budget.

Customs and Compliance Issues

Not preparing proper documentation or understanding import/export requirements.

Solution: Work with experienced logistics partners and prepare all documentation in advance.

Best Practices for Success

Research Thoroughly

Understand your requirements, regulations, and market standards before starting.

Choose Reliable Partners

Work with experienced suppliers who understand your industry and requirements.

Communicate Clearly

Maintain clear communication throughout the process to avoid misunderstandings.

Why Choose Us - Your Premium Partner

for Food Packaging Excellence

Certified quality, proven expertise, and unwavering commitment to delivering packaging solutions that elevate your brand and protect your products.

Decade of Mastery

Over 10 years of specialized expertise in premium food packaging, serving thousands of successful brands worldwide with innovative, market-leading solutions.

Certified Excellence

Rigorous quality control processes, internationally certified materials, and comprehensive testing protocols ensure every product exceeds industry standards.

Dedicated Partnership

Personal account managers, round-the-clock customer support, and expert consultation throughout your entire project journey from concept to delivery.

Smart Investment

Direct manufacturer pricing eliminates middlemen costs, while volume discounts and transparent pricing structures ensure maximum value for your investment.

Lightning Delivery

Streamlined production workflows, advanced manufacturing capabilities, and flexible scheduling ensure rapid turnaround without compromising quality.

Earth-Conscious Solutions

Sustainable materials sourcing, recyclable packaging options, and carbon-neutral manufacturing processes that protect our planet for future generations.

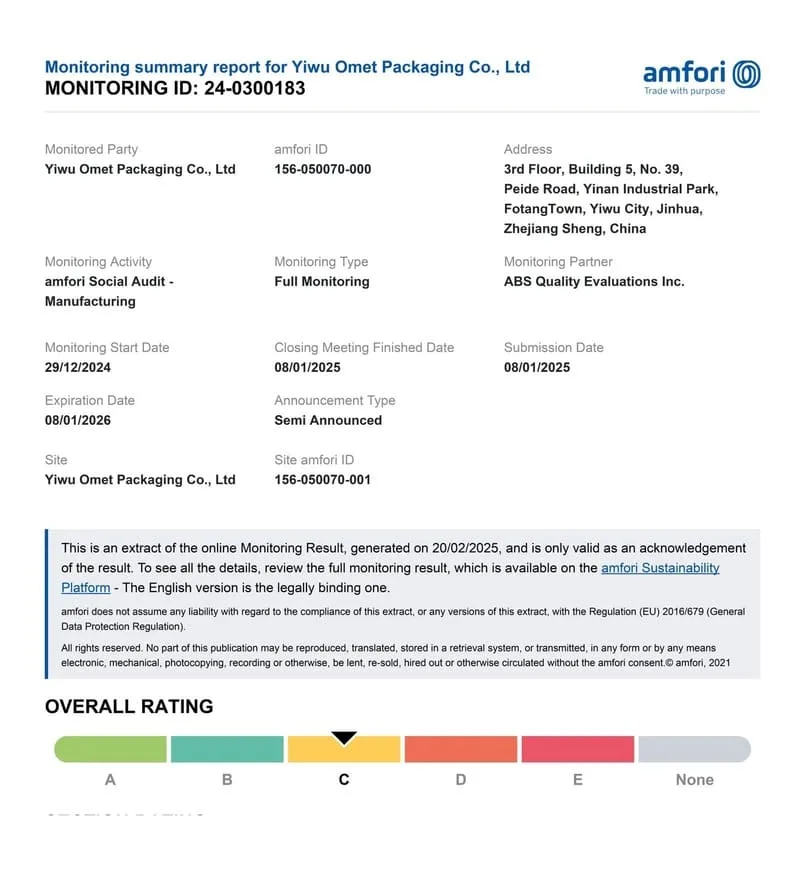

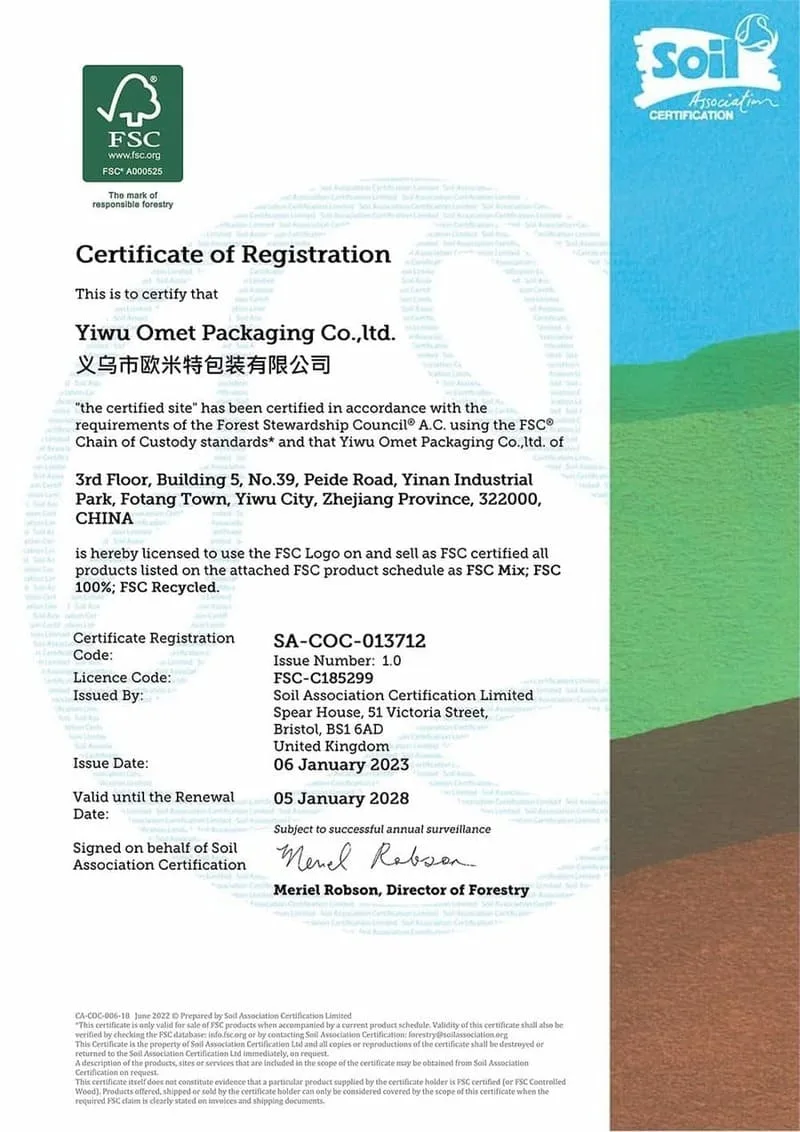

Backed by International Certifications

Our commitment to excellence is validated by globally recognized certifications that ensure quality, sustainability, and ethical business practices.

BSCI Social Compliance

Business Social Compliance Initiative certification demonstrates our commitment to ethical labor practices, safe working conditions, and social responsibility throughout our supply chain.

FSC Forest Stewardship

Forest Stewardship Council certification ensures all our paper-based materials originate from responsibly managed forests, supporting global sustainability initiatives.

Our Ironclad Promise to You

When you partner with us, you're not just buying packaging – you're investing in a relationship built on trust, quality, and mutual success.

What We Guarantee

How We Excel

Join 10,000+ satisfied customers who trust us with their packaging needs

What Our Clients Say

Read honest, verified reviews from food brands that use our custom packaging—from chocolate gift boxes to pizza and cake boxes. Teams consistently highlight our print accuracy, food‑safe materials, sustainable options, and on‑time delivery.

Product: Custom Chocolate Gift Boxes

Rigid board • CMYK + Pantone • Soft‑touch finish

"These chocolate boxes turned out gorgeous. Colors matched our Pantones, the soft‑touch feels premium, and customers keep posting unboxing pics. Zero smudges, zero hassle."

Product: Grease‑Resistant Pizza Boxes

Heavy‑duty kraft • Food‑safe inks • Crisp die‑cut

"No fuss, just solid pizza boxes. They helped pick the right board so the pies stay crisp, print looks sharp, and everything arrived on time for our promo weekend."

Product: Window Cake Boxes

Clear window • Food‑grade board • Fast‑fold design

"We got physical samples first, which was a game‑changer. The window shows off our frosting, the boxes fold fast, and the whites are actually white—not yellowish. Love it."

Product: Foil‑Stamped Corporate Gift Boxes

Gold foil • Rigid setup • Premium insert

"We had a tight deadline and needed a luxe look. The hot‑foil stamp is clean, registration is spot‑on, and the price made sense. Our client literally said, ‘Wow.’"

Product: Recyclable Cookie Boxes (FSC)

FSC paper • Plastic‑free • Clear recycling icons

"Sustainability matters to us. FSC paper, plastic‑free options, and clear recycling info on the flap—exactly what we needed without losing that premium feel."

Product: Food‑Safe Cups & Takeaway Packaging

Compliant inks • Lot codes • Audit‑ready docs

"They know food‑safe rules cold. We got all the documentation, inks are compliant, and the lot codes print consistently. Passed our audits with room to spare."

Customer Satisfaction Statistics

Customer Satisfaction

On‑Time Delivery

Happy Clients

Years Experience

Let's create packaging that makes your customers as happy as these reviews!

Got Questions?

We Have Answers

Everything you need to know about food packaging solutions, materials, and our process. Find instant answers to the most common questions from food businesses worldwide.

What's your minimum order quantity for food packaging?

What's your minimum order quantity for food packaging?

Our minimum order starts at just 500 pieces for most food packaging items. However, we recommend ordering 3,000+ pieces for better unit pricing. Sweet spot for cost efficiency? 5,000-10,000 pieces - that's where you get our most competitive rates and fastest turnaround times.

How fast can you produce my food packaging?

How fast can you produce my food packaging?

Total timeline: 30-45 days from order confirmation to delivery. Here's the breakdown:

- • Design finalization: 1-3 days

- • Sample production: 7-10 days

- • Mass production: 20-30 days

- • Shipping: 7-55 days (depending on method)

Are all your materials completely food-safe?

Are all your materials completely food-safe?

Absolutely! All our materials are FDA-approved and certified for direct food contact. We use only food-grade inks, coatings, and substrates. Our facilities maintain strict HACCP standards, and we provide full material safety documentation with every order.

Can you match my exact brand colors perfectly?

Can you match my exact brand colors perfectly?

Yes, we're color-matching experts! We can precisely match any Pantone color or create custom color profiles from your brand guidelines. We provide color proofs for approval and use spot color printing for exact consistency across all your packaging.

Do you create completely custom sizes and shapes?

Do you create completely custom sizes and shapes?

Absolutely! Custom sizing is our specialty. Just provide your product dimensions, and we'll design packaging that fits perfectly. Whether it's unique shapes, specific heights, or complex folding patterns - we create exactly what your products need.

What payment terms and methods do you accept?

What payment terms and methods do you accept?

Flexible payment options: 50% deposit to start, 50% before shipping. We accept:

- • Wire transfers (T/T)

- • Bank transfers

- • Letter of Credit (for larger orders)

- • PayPal (for smaller orders)

Can I get physical samples before ordering?

Can I get physical samples before ordering?

Of course! We strongly recommend sampling before bulk production. Physical samples take 7-10 days to produce and can be shipped worldwide. Sample costs are fully credited back when you place your production order.

What certifications and standards do you maintain?

What certifications and standards do you maintain?

We maintain the highest industry standards:

- • BSCI Certified - Ethical manufacturing

- • FSC Certified - Sustainable forestry

- • ISO 9001 - Quality management

- • FDA Compliant - Food safety standards

How do you help me choose the right materials?

How do you help me choose the right materials?

We're your material experts! Our team analyzes your product's specific needs - weight, temperature, moisture, shelf life - then recommends the perfect combination of materials, coatings, and finishes. We consider your budget, sustainability goals, and brand image.

What shipping options do you offer worldwide?

What shipping options do you offer worldwide?

Global shipping solutions:

- • Express shipping: 7-10 days (DHL, FedEx, UPS)

- • Air freight: 15-20 days (cost-effective)

- • Sea freight: 30-55 days (most economical)

- • Door-to-door service with customs clearance included

Still Have Questions?

Our packaging experts are standing by to help with any specific questions about your project.