Confused about whether your beautifully printed paper bags can actually be recycled? You’ve invested in sustainable packaging, but complex rules about coatings, inks, and handles make it a frustrating guessing game for both you and your customers.

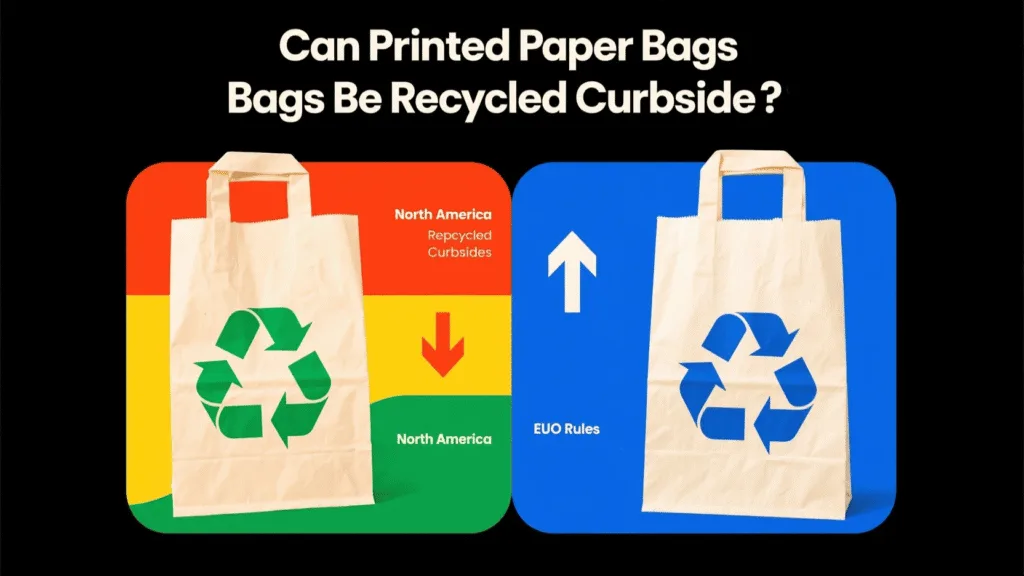

Yes, most printed paper bags can be recycled curbside, but their recyclability depends entirely on the materials used. Add-ons like plastic lamination, foil, and glitter will get them rejected. The rules also vary significantly, with North America having localized guidelines and the EU enforcing more harmonized standards.

As the founder of Yiwu Omet Packaging, I’ve seen brands pour their hearts into designing stunning custom paper bags only to discover their creation is destined for a landfill. This isn’t just an environmental issue; it’s a brand integrity issue. Your customers choose you partly for your values, and packaging is a tangible symbol of that commitment. The confusion between what’s technically possible and what’s practically accepted at recycling centers is a huge hurdle. Let’s clear the air and break down the real rules for North America and the EU.

What Makes a Standard Printed Paper Bag Recyclable?

You assume that "paper" automatically means "recyclable," right? The problem is, the inks, glues, and shiny finishes on your bags could be contaminants that ruin an entire batch of recycled pulp, undermining your brand’s green intentions.

A standard printed paper bag is recyclable if it’s primarily made of paper fiber, uses eco-friendly inks like soy or water-based formulas, and features easily removable or paper-based handles. The goal is to minimize non-paper components that disrupt the paper recycling process.

The journey of a paper bag at a recycling facility is straightforward but sensitive. It gets mixed with water and churned into a slurry called pulp. Screens and filters then remove contaminants like plastics, metals, and glues. If a bag has too many of these non-paper elements, it gets filtered out and sent to the landfill. I once worked with a startup that wanted a vibrant, high-gloss bag for their gift packaging. Their initial design included a plastic laminate finish. I explained that while it looked great, it would make the bag non-recyclable in most places. We switched to an aqueous coating—a water-based varnish that provides a nice sheen without the plastic film. This small change allowed them to market their packaging as 100% recyclable, which was a huge win for their eco-conscious brand. It’s these material choices that make all the difference.

The Anatomy of a Recyclable Bag

To design for recyclability, you need to think about every component. The goal is to create a "mono-material" product as much as possible, meaning it’s made from a single type of material (paper). When other materials are necessary, they should be easy to separate. Here’s a breakdown of what works and what doesn’t:

- The Paper Itself: Kraft, white, and recycled paper are all excellent choices. The key is that they are clean and free from food waste or grease.

- The Inks: The type of ink is more important than the amount of coverage. Soy-based and water-based inks1 are designed to separate easily from paper fibers during the pulping process. Traditional petroleum-based inks can be more difficult to remove.

- The Finishes: This is where most bags fail. A thin, water-based varnish or aqueous coating can add protection and sheen without compromising recyclability. However, plastic lamination (both gloss and matte) is essentially a thin film of plastic bonded to the paper, making it a contaminant.

- The Handles: Paper-twist handles are ideal because they are made of the same material as the bag. Natural fibers like cotton or jute are often acceptable, as they can be filtered out. Plastic or heavily synthetic ribbon handles should be removed by the consumer before recycling.

- The Glues: Most modern adhesives used in bag manufacturing are designed to be water-soluble and break down during pulping.

Here is a simple table to guide your design choices:

| Component | Recyclable Choice | Non-Recyclable Choice |

|---|---|---|

| Paper Stock | Kraft, Recycled Paper, Art Paper | Wax-coated or Greaseproof Paper |

| Ink | Soy-based or Water-based Ink | Petroleum-based Inks, Metallic Inks |

| Finish/Coating | Aqueous (Water-based) Coating, Varnish | Plastic Lamination (Gloss or Matte), Glitter |

| Embellishments | Simple Embossing or Debossing | Foil Stamping, Plastic Windows |

| Handles | Paper Twist, Cotton, Jute | Polypropylene Rope, Plastic Tubes, Satin Ribbon |

How Do Recycling Rules Differ in North America (USA & Canada)?

You’ve designed a beautiful, seemingly recyclable bag for your North American launch. But are you confident it will be accepted in the recycling bin in every state, province, or city where your customers live?

In North America, curbside recycling rules are highly fragmented and managed at the municipal level. While most programs accept clean paper bags, those with heavy ink, plastic coatings, or foil are frequently rejected. Consumers must check local guidelines, as there is no single national standard.

The lack of a federal recycling mandate in the United States and Canada creates a confusing patchwork of regulations. What’s recyclable in San Francisco, with its advanced sorting facilities, might be considered trash in a smaller town in the Midwest. This creates a huge challenge for national brands. A few years ago, a client of mine who sells cosmetic packaging across the U.S. ran into this issue. Their bag used a very dark, full-coverage ink. In some municipalities, this was flagged as a contaminant because optical sorters couldn’t properly identify the paper fiber underneath. We had to adjust the design to incorporate more un-printed "white space," which solved the problem. This experience taught me to always advise my North American clients to design for the strictest programs. A helpful tool emerging to combat this confusion is the How2Recycle label, which provides clear, location-aware instructions for consumers, but its adoption is still voluntary.

Without a unified system, brands must focus on creating packaging that is acceptable to the widest possible audience. The main culprits for rejection in North American curbside programs are contamination and mixed materials.

- The "Clean Stream" Rule: All recycling facilities emphasize that paper must be clean and dry. A paper bag used to carry a greasy takeout container, for instance, is no longer recyclable because the oils have contaminated the fibers. This is a consumer education issue that brands can help with by printing a small reminder on the bag.

- Lamination and Coatings: This is the most common reason a printed bag gets rejected. Plastic lamination is a definite "no." Many facilities also struggle with heavy UV coatings or soft-touch finishes that behave like plastic.

- "Wishcycling": This is the term for when consumers hopefully toss non-recyclable items into the bin, thinking they might get recycled. This practice actually harms the recycling system by contaminating good material and increasing sorting costs. As a brand, your best defense is clear communication and simple design. If your bag has a plastic handle, add a small icon or text prompting the user to "Remove Handle Before Recycling."

Ultimately, designing for the North American market requires a "lowest common denominator" approach. Stick to simple paper, eco-friendly inks, and avoid the complex finishes that will only cause confusion and lead your well-intentioned packaging straight to the landfill.

What Are the Curbside Recycling Guidelines in the European Union?

Expanding your brand into the European Union is a huge milestone. But their strict, unified packaging laws could reject your current design, forcing costly changes and creating compliance headaches you didn’t anticipate.

The European Union operates under more harmonized recycling standards, driven by legislation like the Packaging and Packaging Waste Regulation. There is a strong emphasis on producer responsibility (EPR), and paper bags with bonded materials like plastic laminates are generally not accepted in the paper recycling stream.

Unlike North America’s fragmented system, the EU takes a top-down approach. Directives from the European Commission set targets for recycling rates that all member countries must meet. This has led to the creation of powerful systems like Extended Producer Responsibility (EPR). In simple terms, EPR schemes require companies that place packaging on the market to pay fees that fund its collection and recycling. These fees are often higher for packaging that is difficult to recycle. I worked with a client launching a line of jewelry packaging in Germany and France. Their initial box design featured a small plastic window to display the product. Under the German and French EPR laws, this mixed-material design would have incurred significantly higher fees. We redesigned the box to be 100% paperboard. This not only lowered their EPR fees but also strengthened their brand’s sustainable image in a market that is highly critical of packaging waste. This is the power of the EU system: it uses financial incentives to push brands toward better design.

Key Differences: North America vs. EU

The philosophical and practical differences in how these two massive markets approach recycling are stark. Understanding them is key to designing packaging that works globally. A manufacturer with experience in both markets is an invaluable partner in navigating these rules.

| Feature | North America (USA & Canada) | European Union |

|---|---|---|

| Regulatory Framework | Decentralized, managed at state/provincial and municipal levels. | Harmonized, driven by EU-wide directives and national laws. |

| Key Driver | Municipal budgets and commodity markets for recycled materials. | Extended Producer Responsibility (EPR) fees1 and recycling targets. |

| Consumer Labeling | Voluntary labels like How2Recycle are gaining traction. | Mandatory symbols like the Triman logo (France) are common. |

| View on Mixed Materials | Often rejected as contamination. | Financially penalized; strong push for mono-material design2. |

| Brand Responsibility | Primarily focused on truthful marketing claims (e.g., FTC Green Guides). | Legally and financially responsible for end-of-life management. |

For any brand with global ambitions, designing for the EU’s stricter, mono-material standards is the smartest long-term strategy. Packaging that is compliant in Germany, France, and Spain will almost certainly be accepted in any curbside program in North America. The reverse is definitely not true.

Conclusion

The recyclability of your printed paper bag isn’t a simple yes or no question—it’s a matter of design, material choice, and geography. To ensure your packaging is truly sustainable, opt for simple, mono-material designs with eco-friendly inks and avoid contaminants like plastic laminates and foil, especially for the EU market.

Ready to design beautiful, compliant, and recyclable packaging for your global brand? Contact us at Yiwu Omet Packaging for a consultation.

Check out our blog for more insights on making your packaging a competitive advantage.

FAQ

1. Are paper bags with glossy finishes recyclable?

It depends entirely on how the gloss is achieved. If it’s a water-based aqueous coating or a recyclable UV varnish, it is generally recyclable. If the glossy finish comes from a plastic film lamination, the bag is not recyclable in most curbside programs.

2. What should I do with the handles before recycling a paper bag?

For the best results, remove any non-paper handles. Handles made from polypropylene rope, plastic tubes, or synthetic ribbons should be detached and thrown in the trash. Paper twist handles can be left on, as they will be pulped along with the bag.

3. Does heavy ink coverage prevent a bag from being recycled?

While very heavy, dark ink coverage (especially solvent-based) can sometimes pose a challenge for de-inking facilities, the type of ink is more important. Modern recycling processes can handle most printed paper, especially when soy-based or water-based inks are used. The bigger issue is non-paper additions like foil or glitter.