Your bakery is thriving, but your packaging is holding you back. Flimsy boxes crush your beautiful creations, and you have no idea how to start shipping beyond your neighborhood without everything arriving in a mess.

To scale your bakery’s packaging, you must transition through three key stages: perfecting branded local pickup boxes, developing a protective "box-in-a-box" system for regional delivery, and finally, engineering temperature-controlled kits for safe nationwide shipping. This ensures your brand and products are protected as your reach grows.

I once worked with a small bakery that made the most incredible pies. They were a local sensation. When they decided to offer delivery to the next county over, they just put their standard pink pickup boxes into the hands of a courier. The calls started coming in almost immediately. Pies had shifted, crusts were broken, and the beautiful boxes were dented. They were trying to solve a shipping problem with a presentation box. It was a classic case of growing pains. We had to sit down and map out a completely new strategy, starting with the idea that as your distance to the customer grows, so must the layers of protection around your product.

How Do You Perfect Your Local Pickup Packaging?

Your pickup boxes are generic and flimsy. They don’t protect your baked goods properly and fail to make a lasting impression on your local customers, who are your most loyal supporters.

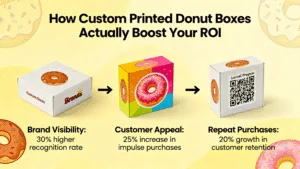

Perfecting local pickup packaging means focusing on structural integrity and cost-effective branding. Use sturdy, food-safe paperboard for protection and add branded elements like stickers or stamps to create a professional experience without a large investment.

For a bakery just starting out, the in-store experience is everything. Your packaging is a huge part of that. It’s the last thing your customer interacts with before they leave. I’ve seen so many new bakery owners spend a fortune on their ovens and mixers but then grab the cheapest, plainest stock boxes they can find. This is a missed opportunity. Your local pickup box doesn’t need to be complicated or expensive. We often start clients with high-quality kraft or white paperboard boxes that have an auto-bottom design for quick assembly during busy hours. For branding, we skip expensive printing and go for a custom rubber stamp with their logo or a roll of branded stickers to seal the box. It’s affordable, looks artisanal, and instantly elevates the perceived value of their products. It turns a simple container into a piece of marketing that walks out the door with every customer.

Start with a Strong Foundation

The box itself must be functional before it can be beautiful.

- Material Matters: Choose a sturdy paperboard (measured in points, like 18pt or 24pt) that won’t bend or collapse. Ensure it’s made from food-safe materials.

- Smart Structural Design1: Features like locking tabs, auto-bottoms for easy assembly, and clear window patches to showcase your creations are practical and enhance the customer experience.

Brand Your Boxes on a Budget

You don’t need a massive budget to create a memorable brand experience.

- Stickers and Labels: Custom-printed stickers are a versatile and low-cost way to add your logo and contact information to any stock box.

- Rubber Stamps: A custom stamp with food-grade ink offers a rustic, hands-on feel that is very affordable for small batches.

- Belly Bands: A simple printed paper band wrapped around the box can add a splash of color and branding information for a minimal cost.

| Branding Method | Per-Unit Cost | Minimum Order | Brand Impact |

|---|---|---|---|

| Custom Stickers2 | Low | Very Low (e.g., 100) | Good |

| Custom Stamps | Very Low | One-time purchase | Good (Artisanal) |

| Belly Bands | Low-Medium | Medium (e.g., 250) | Great |

| Full Custom Print | High | High (e.g., 1000+) | Excellent |

What’s Required for Shipping Regionally?

You’re ready to expand, but your local pickup boxes are getting crushed in transit. Every damaged delivery means an unhappy customer, a costly refund, and a blow to your brand’s reputation.

Shipping regionally requires a "box-in-a-box" system. Your decorated primary bakery box is placed inside a durable, corrugated shipping mailer, with void fill like crinkle paper used to cushion it and prevent any movement during transit.

Thinking about regional shipping is a big step. The key mindset shift is realizing you are now packaging for the "last mile," which can be rough. I always share an observation from my time visiting a shipping hub. I saw packages being tossed, stacked high, and sent down conveyor belts. Your pretty little pickup box stands no chance on its own. This is where the box-in-a-box method becomes essential. The inner box’s job is presentation. The outer box’s job is to take all the punishment. We helped one cookie company make this transition. We designed their inner box to fit perfectly inside a standard-sized corrugated mailer, leaving just enough space for a cushion of crinkle paper. This simple system eliminated 99% of their breakage issues and allowed them to confidently expand their delivery zone to three neighboring states. It’s a straightforward solution that protects both the product and the unboxing experience.

The Anatomy of a Regional Shipping Kit

This system has two main protective components.

- The Outer Shipper: This should be a strong corrugated cardboard box, often called a mailer or an RSC (Regular Slotted Container). Look for boxes with a high edge crush test (ECT) rating, like 32 ECT, which is standard for most shipping carriers. It’s the armor for your product.

- The Void Fill1: This is the material that fills the empty space between the inner and outer box. Its job is to absorb shock and prevent movement. Options include crinkle paper, bubble wrap, or air pillows. Kraft crinkle paper is a popular, eco-friendly choice.

Getting the Details Right

Small things make a big difference in successful shipping.

- Proper Sizing2: The outer box should be just large enough to fit the inner box plus about one to two inches of cushioning on all sides. Too much empty space requires more void fill and increases the risk of shifting.

- Secure Sealing: Use high-quality pressure-sensitive packing tape. Don’t cheap out here. A box that opens in transit is a total loss.

- Follow Carrier Guidelines: Each carrier, like UPS or FedEx, has specific guidelines for packaging. Following them can help if you ever need to file a damage claim.

How Do You Build a Nationwide Shipping Kit?

You dream of shipping across the country, but your frosted cakes, delicate pastries, and cheesecakes will never survive the long journey and temperature changes. This limitation is capping your growth potential.

A nationwide shipping kit must include temperature control. This involves adding insulated liners and gel packs to your box-in-a-box system, along with custom inserts to immobilize products and prevent moisture damage from condensation.

Building a nationwide shipping kit is the final frontier for a small bakery. It’s as much about food science as it is about packaging. I always tell my clients at this stage: you have to become a logistics expert. The biggest hurdle is temperature. We worked with a chocolatier who wanted to ship her delicate truffles from Florida to California in July. We had to build a complete cold chain system. This included a thick foam cooler inside a corrugated box, enough gel packs to last 72 hours, and even sealing the truffles in an inner bag to protect them from condensation as the packs thawed. The most important part of the process? We did a trial run. I had her ship me a test box. When it arrived, we opened it together over a video call. Seeing the condition of the product firsthand is the only way to know if your system works. Testing is not optional at this level; it’s essential for success.

The Essentials of Temperature Control

You must create a stable, cool environment inside your package.

- Insulation: This is your barrier against external heat. Options range from flexible bubble foil liners, which are great for 24-48 hour transit, to thick expanded polystyrene (EPS) foam coolers for maximum protection on longer journeys.

- Coolants1: Gel packs are the industry standard for refrigerated items. The number and size you need depend on the box volume, the amount of insulation, and the expected transit time.

Advanced Product Protection

At this stage, every detail matters for product integrity.

- Custom Inserts2: For items like cupcakes or macarons, custom-designed paperboard or plastic inserts are crucial. They hold each item in place, preventing them from touching and smearing.

- Moisture Barriers: Condensation is the enemy. As gel packs thaw, they create moisture. Sealing your primary bakery box or the products themselves in a plastic bag can protect them from getting soggy.

| Shipping Stage | Primary Box | Outer Protection | Key Add-ons |

|---|---|---|---|

| Local Pickup | Branded Paperboard Box | A carry handle or bag | None |

| Regional Shipping | Paperboard Box | Corrugated Mailer | Void Fill (Crinkle Paper) |

| Nationwide Shipping | Paperboard Box / Sealed Tray | Insulated Mailer/Cooler | Gel Packs, Inserts |

Conclusion

Scaling your bakery’s packaging is a journey from simple presentation to complex logistics. By methodically progressing from perfecting local pickup boxes, to adopting a box-in-a-box system for regional shipping, to mastering temperature control for nationwide delivery, you can grow your business without limits.

Ready to take the next step in your bakery’s growth? Explore our custom paper boxes or contact our team for a consultation on your shipping solution needs.

FAQ

What’s the most cost-effective way to start custom branding my boxes?

The most budget-friendly methods are using custom-printed stickers or a branded rubber stamp with food-grade ink. Both options allow you to brand stock boxes with a very low initial investment, making them perfect for bakeries just starting out.

How do I know how many gel packs to use for shipping?

This depends on your box size, insulation type, transit time, and the outside temperature. A good starting point is one pound of gel pack for every cubic foot of insulated space for 24 hours of transit. Always perform test shipments to verify.

Can my local pickup boxes also be used for shipping?

Yes, but only as the inner box in a box-in-a-box system. A standard pickup box is designed for presentation, not for the rigors of transit, and will almost certainly be damaged if shipped on its own.

What is the best material for bakery boxes?

For direct food contact, Solid Bleached Sulfate (SBS) paperboard is a premium, food-safe choice. For a more natural look, Kraft paperboard is a great, sturdy, and often recycled option. Always ensure any material you choose is certified food-grade.

How far in advance should I order custom packaging?

For fully custom-printed packaging, the process from design to delivery can take anywhere from 4 to 8 weeks. It’s best to plan ahead, especially before busy seasons like holidays, to ensure you don’t run out of supplies.