You proudly market your brand as sustainable and choose "recyclable" gift wrapping paper. But you have a nagging fear that the glitter, shiny finish, and vibrant inks might be sending it straight to the landfill, making your efforts feel like a lie.

Truly recyclable gift wrapping paper must be 100% paper. This means using uncoated or clay-coated paper stock, specifying soy or water-based inks, and completely avoiding non-paper contaminants like plastic coatings, glitter, and foil stamping.

I’ll never forget the call I got from a municipal recycling facility manager. A large local company had run a huge holiday promotion using custom wrapping paper they’d bought from another supplier, proudly telling customers it was "recyclable." The paper was covered in a fine, beautiful red glitter. The manager told me that entire truckloads of paper had to be diverted to the landfill because the glitter was acting as a contaminant, impossible to separate from the paper pulp. The brand thought they were doing the right thing, but their lack of knowledge created a massive waste problem. That conversation solidified my mission to educate my clients on what "recyclable" really means in practice.

Is That Shiny Finish Making Your Paper Unrecyclable?

You love the premium, luxurious look of a glossy finish on your gift wrap. It makes your branding pop. But you’re worried that this beautiful sheen might be the very thing that makes your paper trash.

That shiny finish is often a thin layer of plastic laminated to the paper, rendering it completely non-recyclable. To ensure recyclability, you must choose uncoated paper or a paper with a recyclable clay-based matte coating.

The single easiest way to check if a paper is recyclable is the "rip test." Try to tear it. If it tears cleanly and easily, it’s likely just paper. If it stretches, feels tough to tear, or you see a thin, clear film peeling away, you’re holding paper laminated with plastic. We at Omet Packaging always walk our clients through this reality. I once had a high-end jewelry brand that was adamant about using a "velvet touch" finish for their jewelry packaging solution. It feels incredibly luxurious, but it’s a plastic film. I had to be direct and tell them, "You can have this luxurious feel, or you can have a recyclable product, but you can’t have both with this finish." We ultimately found a beautiful, heavy-weight uncoated recycled paper that conveyed a different kind of luxury—one rooted in authenticity and sustainability.

Understanding Coatings and Finishes

Not all coatings are created equal. The distinction is critical for any brand that cares about what happens to its packaging after the unboxing.

| Coating Type | Description | Recyclability |

|---|---|---|

| Plastic Lamination (Gloss, Matte, Velvet)1 | A thin film of plastic bonded to the paper surface. | No. It is a primary contaminant. |

| UV Coating | A liquid polymer cured with ultraviolet light to create a high-gloss finish. | No. It is a plastic coating that cannot be separated. |

| Aqueous Coating2 | A water-based coating that provides a slight sheen and scuff resistance. | Yes. It is water-soluble and easily breaks down. |

| Clay Coating | A coating of kaolin clay and binders used to create a smooth, bright printing surface. | Yes. This is standard for most magazines and high-quality paper. |

Could Your Choice of Ink Send Your Paper to the Landfill?

Your brand colors are specific and vibrant, and you need them to be reproduced perfectly. But you’ve heard that some inks can be toxic or difficult to recycle, and you don’t want your color choice to undermine your green credentials.

While most modern inks are designed to be removed during recycling, specifying vegetable or soy-based inks is the best practice. These inks are biodegradable and release fewer volatile organic compounds (VOCs), making the de-inking process cleaner and more environmentally friendly.

The process of recycling paper involves a step called "de-inking," which is essentially a giant washing machine that separates the ink from the paper fibers. Petroleum-based inks create a sludge that is difficult to break down and must be disposed of, often in a landfill. Soy-based inks, on the other hand, are much easier to separate from the pulp. A few years ago, we helped a large organic food company switch their entire food packaging line to soy-based inks. The color vibrancy was nearly identical, and the cost increase was minimal, but it allowed them to add "Printed with Soy Inks" to their packaging. This small change became a huge marketing win, reinforcing their brand’s commitment to natural and sustainable practices in a way their customers could see and appreciate.

The Impact of Different Ink Types

The choice of ink has a direct effect on the quality of the recycled paper pulp and the environmental impact of the recycling process itself.

| Ink Type | Environmental Impact | Recyclability | Performance |

|---|---|---|---|

| Petroleum-Based1 | High in VOCs (Volatile Organic Compounds), creates toxic sludge. | Technically recyclable, but the process is less clean. | Standard, wide color gamut. |

| Soy/Vegetable-Based2 | Low VOCs, biodegradable, easier to remove from paper pulp. | Excellent. The preferred choice for green printing. | Excellent color, can sometimes take longer to dry. |

| Metallic Inks | Can contain actual metal particles that contaminate the pulp. | Problematic. Often rejected by recycling facilities. | Creates a shimmer effect, but not true foil. |

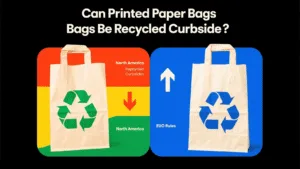

Are "Extras" Like Glitter and Foil Ruining Your Sustainability Efforts?

A touch of gold foil or a sparkle of glitter makes your Christmas gift wrap feel festive and special. But these attractive additions might be the worst offenders when it comes to recyclability.

Yes, absolutely. Glitter, foil, ribbons, and bows are considered major contaminants in the paper recycling stream. They are not paper, cannot be separated by the machinery, and can ruin entire batches of recycled pulp, forcing everything to be landfilled.

I’ve walked the floor of enough paper mills to see what happens when these contaminants get through. Glitter particles are tiny bits of plastic that are impossible to filter out. They get embedded in the new paper, weakening its structure and making it unusable. Hot foil stamping, which is essentially bonding a layer of metallic plastic to the paper, is just as bad. It clogs the screens of the pulping machines. If you want that metallic look, a much better alternative is to use metallic ink, but even then, you should check with your print supplier about its recyclability. The safest, most responsible choice is to create visual excitement through great graphic design on 100% paper. Let the pattern and color be the "special effect," not a material that will doom your product to a landfill.

The Contaminant Hall of Shame

To make your paper truly recyclable, you must avoid these common additions at all costs.

- Glitter1: It’s a microplastic nightmare for recyclers.

- Foil Stamping2: This is a layer of metallicized plastic that cannot be separated from the paper fiber.

- Ribbons & Bows: Whether fabric or plastic, these are not paper and will be filtered out and sent to landfill.

- Excessive Tape: A small amount is acceptable, but large amounts of plastic tape can cause issues. Encourage customers to remove it.

Conclusion

Making gift wrapping paper truly recyclable isn’t a mystery—it’s a conscious choice. It means prioritizing uncoated paper, using soy-based inks, and embracing creative designs that don’t rely on polluting extras like glitter and foil. True sustainability is about understanding the entire life cycle of your product.

Ready to design beautiful, genuinely recyclable gift wrap for your brand? Contact us at Omet Packaging. We’ll help you navigate these choices to create packaging that is both stunning and sustainable.

Learn more about making smart paper choices by reading our guides on FSC Certification and the trade-offs between Kraft, Coated, and Recycled papers.

FAQ

What is the "rip test" for wrapping paper?

The "rip test" is a simple way to check for plastic coatings. Take a piece of the paper and tear it. If it rips easily with a fibrous edge, it’s likely just paper. If it stretches, resists tearing, or a thin film peels off, it has a plastic lamination and is not recyclable.

Is brown kraft paper always recyclable?

Yes, as long as it is not coated with plastic. Standard brown kraft paper is one of the most easily recycled types of paper due to its long fibers and lack of bleaches or heavy coatings.

Does an FSC® certification mean the paper is recyclable?

No, not necessarily. The FSC (Forest Stewardship Council) certification refers to the origin of the wood fiber—guaranteeing it comes from responsibly managed forests. It does not provide any guarantee about the paper’s recyclability. You can have FSC-certified paper that is then coated in plastic and glitter, making it non-recyclable.

What about hot foil stamping? Can that be recycled?

No. Hot foil stamping applies a thin layer of metallic plastic film to the paper using heat and pressure. This film cannot be removed during the de-inking process and is a major contaminant in the paper recycling stream.