You want to switch to sustainable packaging for your desserts, but you’re worried it will be too expensive and complicated. The world of "eco-friendly" claims, certifications, and new materials feels overwhelming.

You can successfully switch by understanding the true cost drivers, focusing on legitimate certifications like FSC, and using a simple checklist to vet suppliers. This approach makes sustainability both achievable and a powerful asset for your brand.

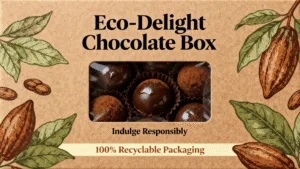

I’ve seen this confusion firsthand. A chocolatier I know was being pitched dozens of "green" box options. Some were made from bamboo, others from recycled plastic, some just had a green leaf printed on them. He was paralyzed by choice and afraid of being accused of "greenwashing" if he picked the wrong one. We sat down and cut through the noise. We focused on one thing: a simple, elegant box made from FSC-certified paperboard. It was 100% recyclable, came from a responsibly managed source, and the certification was easy for his customers to understand and trust. It wasn’t the most exotic option, but it was honest, effective, and beautiful. This experience taught me that the best sustainable choice is often the clearest one.

What Really Drives the Cost of Sustainable Dessert Boxes?

You hear the word "sustainable" and immediately assume it means "expensive." This fear holds you back from exploring options that could actually strengthen your brand and attract environmentally conscious customers.

The cost of sustainable dessert boxes is mainly influenced by three things: the raw material (recycled vs. virgin FSC), the complexity of the design, and your order volume. Often, smart design can reduce material use and offset the cost of premium, eco-friendly paper.

The price tag on sustainable packaging isn’t arbitrary. The biggest factor is the raw paper stock. Virgin paper from an FSC-certified forest, which ensures responsible management, can sometimes cost more than non-certified paper. Conversely, high-quality recycled paperboard can also carry a premium due to the processes required to de-ink and create a food-safe product. The second factor is operational. Eco-friendly, food-safe inks (like soy-based inks) might have a slightly higher cost than standard petroleum-based inks. Finally, design and efficiency play a huge role. A complex box with many folds, glue points, and a separate plastic window will cost more than a simple, self-closing "crash-lock" box made entirely from paperboard. However, this is also where you can save. I always encourage clients to think about structural design. A clever fold or tuck can eliminate the need for glue, and a larger order volume will always bring the per-unit cost down significantly. It’s a balance of material choice, design intelligence, and production scale.

Key Cost Factors Breakdown

Understanding these components allows you to make informed trade-offs to meet your budget and sustainability goals.

The Volume Advantage

As with any custom manufacturing, larger production runs distribute the setup costs over more units, drastically lowering the price per box. Planning your inventory and ordering for a quarter or half-year instead of month-to-month can lead to substantial savings.

| Cost Component | Impact on Price | Sustainability Consideration |

|---|---|---|

| Raw Material1 | High | FSC-certified and high-recycled content papers ensure responsible sourcing. |

| Inks & Coatings | Medium | Soy-based inks and water-based coatings are better for the environment. |

| Structural Design | Medium | Smart designs can reduce material waste and eliminate the need for glue. |

| Order Volume2 | High | Larger orders significantly decrease the cost per unit. |

Which Sustainability Certifications Actually Matter for Paper Packaging?

You’re bombarded with logos and symbols all claiming to be "green," "eco," or "earth-friendly." You don’t know which ones are legitimate third-party verifications and which are just clever marketing, leaving you vulnerable to greenwashing.

For paper packaging, the most crucial certification is from the Forest Stewardship Council (FSC). This verifies the paper comes from responsibly managed forests. Other important marks include B Corp Certification for overall company ethics and compostability certifications for specific materials.

Certifications are your shield against greenwashing. They provide independent, third-party proof that you are making a genuinely responsible choice. In the world of paper, the FSC is the undisputed global standard. It guarantees that the wood fibers used to make your boxes are sourced in a way that protects biodiversity, respects the rights of Indigenous peoples, and ensures the long-term health of the forest. When you see the FSC logo, you know it’s not just a marketing claim; it’s a promise backed by a rigorous chain-of-custody system that tracks the material from the forest to our factory. According to a 2021 study, consumers are increasingly looking for these labels, with over 50% recognizing the FSC logo and trusting it (Source: GlobeScan). While FSC is about the material’s origin, other certifications speak to the bigger picture. B Corp, for example, certifies the entire company’s social and environmental performance, from employee wages to carbon footprint. At Omet Packaging, we hold both FSC and BSCI certifications because we believe sustainability is about the entire supply chain, not just the final product.

The FSC "Chain of Custody"

This is the system that tracks FSC-certified material from the forest through every step of production. A supplier must have a valid Chain of Custody1 certificate to be able to print the FSC logo on your product. You can always ask for their certificate number and verify it on the FSC’s public database.

Beyond the Paper

While FSC is paramount, also look for suppliers with ISO 14001 certification2, which demonstrates a commitment to environmental management within their own factory operations. This shows they are not just buying sustainable paper but are also managing their own waste, water, and energy use responsibly.

What Questions Should You Ask a Potential Sustainable Packaging Supplier?

You’re ready to request a quote, but you don’t know how to look beyond the price. You need to assess if a potential partner is truly an expert in sustainable practices or if they are just saying what you want to hear.

Go beyond price and ask for specifics. A reliable supplier can immediately provide their FSC certificate number, explain their material traceability, detail their experience with food-grade coatings, and advise on design changes to reduce waste.

Finding the right partner is the most critical step. A great supplier is more than a manufacturer; they are a consultant who can guide you to the best and most cost-effective sustainable solution. Over the years, I’ve learned that the best partnerships start with direct questions that cut through the sales pitch. Don’t just ask, "Are you sustainable?" Ask, "Can you please send me a copy of your current FSC and BSCI audit reports?" Don’t just ask, "Can you make a food box?" Ask, "What kind of food-safe, water-based coatings do you use to prevent grease stains, and are they certified compostable?" A knowledgeable and transparent partner will welcome these questions and have answers ready. They should be able to show you examples of similar projects they’ve done and suggest structural modifications to your design that could reduce your material usage by 10-15%. This collaborative approach is the hallmark of a true expert. If a supplier is vague, evasive, or can’t produce documentation, it’s a major red flag.

Your Supplier Vetting Checklist

Use this structured approach to interview potential packaging partners. Their answers will reveal their level of expertise and transparency.

| Category | Key Questions to Ask | What to Look For |

|---|---|---|

| Certifications1 | "What is your FSC certificate number?" "Can I see your latest BSCI audit?" | A valid, easily verifiable certificate number. Transparency and willingness to share reports. |

| Material Sourcing | "Where do you source your paperboard?" "Can you trace the material?" | Clear answers about their supply chain. Knowledge of different paper types (Kraft, SBS, recycled). |

| Food Safety | "What food-grade inks and coatings do you use?" "Are they recyclable/compostable?" | Specifics on water-based coatings and soy-based inks. Understanding of FDA regulations. |

| Expertise & Design | "Can you suggest design changes to reduce waste?" "Show me similar projects." | Proactive advice on "lightweighting" and structural efficiency. A strong portfolio. |

Conclusion

Choosing sustainable dessert packaging for 2025 doesn’t have to be a costly or confusing process. By focusing on the real cost drivers, demanding legitimate certifications like FSC, and using a checklist to vet your suppliers, you can make a choice that is good for the planet and great for your brand.

Ready to find a transparent partner for your sustainable packaging journey? Explore our food-safe packaging solutions or contact us directly to discuss your project.

FAQ

Is compostable packaging always better than recyclable packaging?

Not always. "Compostable" is only beneficial if the packaging ends up in an industrial composting facility, which are not widely available to all consumers. A widely recyclable paper box is often a better choice, as the infrastructure for paper recycling is far more established globally.

What is a typical minimum order quantity (MOQ) for custom sustainable boxes?

MOQs vary by supplier and complexity, but for fully custom offset-printed boxes, they often start between 1,000 to 2,000 units. This is because the initial setup for printing plates and cutting dies is the most expensive part of the process.

Can I still use premium finishes like embossing or hot stamping on sustainable boxes?

Absolutely. Finishes like blind embossing (pressing a design into the paper without ink or foil) are very eco-friendly. Modern hot stamping foils are now so thin that they do not interfere with the recycling process in most modern facilities, allowing you to achieve a luxury look sustainably.