You’re a growing bakery, but choosing the right packaging supplier feels like a gamble. Pick the wrong one, and you could face production delays, poor quality boxes that damage your brand, and a huge financial loss.

To properly compare suppliers for dessert and cake boxes, you must move beyond price and evaluate them on three core pillars: their Minimum Order Quantity (MOQ), stated lead times versus actual delivery speed, and specific Key Performance Indicators (KPIs) for quality. This structured approach protects your brand and budget.

I remember a client, a talented pastry chef launching her first line of macarons. She found a supplier online offering an unbelievably low price. She was so excited about the savings that she ignored the other details and placed a huge order. The boxes arrived two weeks late, missing her product launch. Worse, the color was a dull, faded pink instead of the vibrant shade from her brand guide, and the flimsy paperboard offered no real protection. It was a classic case of getting what you pay for. We had to rush-order a new batch from a reliable partner, and the experience taught her a hard lesson: a procurement guide that starts and ends with price is a recipe for disaster.

What Is the Real Impact of a Supplier’s MOQ?

You’ve found a supplier with a great unit price, but their high Minimum Order Quantity (MOQ) would eat up your entire budget. This ties up your cash in inventory that could become obsolete if you change your branding or product size.

A supplier’s MOQ directly impacts your cash flow, storage costs, and business agility. A low MOQ offers flexibility for small businesses, while a high MOQ provides a lower per-unit cost but requires a significant upfront investment and storage space.

When I first started in this industry, I saw many small businesses get trapped by the allure of a low unit price. They would see that ordering 10,000 boxes drops the price by 30% compared to ordering 1,000. It seems like a smart move. But then the pallets of boxes arrive. Suddenly, they need to find—and pay for—a place to store 9,000 boxes. That cash is now sitting on a shelf, unable to be used for marketing or new ingredients. For a new business, cash flow is oxygen. I always advise startups to prioritize flexibility. It’s often smarter to work with a supplier who can provide a quality box at a 1,000-unit MOQ, even if the per-unit cost is higher. This approach lets you test the market, make design tweaks, and keep your cash free for growth.

The Trade-Off Between Unit Price and Total Cost

Economy of scale1 is a fundamental concept in manufacturing. The more you produce in a single run, the lower the setup costs are per unit.

- High MOQ: Suppliers with large, automated production lines offer the best unit prices but need large orders to be profitable. This is ideal for established brands with predictable sales volumes.

- Low MOQ: Smaller suppliers or those with digital printing capabilities can handle short runs. The per-unit cost is higher, but the total initial investment is much lower, reducing your financial risk.

Finding a Supplier That Fits Your Scale

Your business size should dictate your supplier choice.

- Startups & Small Bakeries: Look for suppliers specializing in small-batch orders. They understand your need for flexibility.

- Growing Businesses: You might work with a mid-size supplier who can offer a balance—a reasonable MOQ of a few thousand units with a competitive price.

- Large Enterprises: High-volume manufacturers, often overseas like us at Omet Packaging, provide the best value for large, consistent orders.

| Factor | Low MOQ Supplier | High MOQ Supplier |

|---|---|---|

| Minimum Order2 | 500 – 1,000 units | 5,000 – 10,000+ units |

| Per-Unit Cost | Higher | Lower |

| Total Investment | Low | High |

| Flexibility | High (Easy to change designs) | Low (Committed to one design) |

| Ideal For | Startups, seasonal items | Established, high-volume brands |

Why Are Accurate Lead Times Crucial for Your Business?

Your supplier promised a four-week delivery, but it’s now week six. Your seasonal promotion is ruined, you have no boxes for your weekend farmers’ market, and your customers are getting impatient.

Accurate lead times are essential for managing inventory, planning product launches, and maintaining operational stability. A supplier’s failure to deliver on time can halt your production, damage your reputation, and result in significant lost revenue.

One of our clients, a bakery chain, was planning a big launch for a new line of holiday-themed cakes. They placed an order with a new supplier who promised an aggressive 30-day lead time from China, right before the holiday rush. What the supplier didn’t clearly communicate was that their 30 days only covered production. It didn’t include the time for ocean freight, potential customs delays, or inland trucking. Port congestion, as reported by firms like Drewry, can add weeks to a shipment. The boxes ended up arriving in early January. They missed the entire holiday season, and the client had to liquidate the now-useless packaging at a huge loss. This is why we are always transparent about breaking down the timeline. A true lead time is from the day you sign off on the proof to the day the boxes land on your doorstep.

Deconstructing the Lead Time

A quoted lead time1 is not a single block of time. It’s made up of several distinct phases.

- Pre-production (5-10 days): This includes finalizing the design, creating die-lines, digital proofing, and producing physical samples for approval.

- Production (15-30 days): This is the actual manufacturing time: printing the sheets, laminating, die-cutting, gluing, and packing the flat boxes.

- Post-production (15-40 days): This phase covers logistics. For overseas suppliers, this includes ocean or air freight, customs clearance, and final delivery to your warehouse.

How to Vet a Supplier’s Quoted Lead Time

Don’t just take their word for it. Do your due diligence.

- Ask for a Detailed Timeline: Request a breakdown of their lead time into the phases above. This shows they have a clear process.

- Inquire About Production Capacity: Ask them how your order fits into their current production schedule. Are they overbooked?

- Start with a Trial Order: Placing a smaller, less critical order first can be a great way to test their real-world performance before committing to a larger one.

Which Quality KPIs Should You Actually Track?

Your supplier said they produce "high-quality" boxes, but the last batch you received had inconsistent colors, weak corners, and a strange chemical smell. The term "quality" is meaningless without specific metrics.

To ensure consistent quality, you must track specific Key Performance Indicators (KPIs): material specifications (paperboard grade and food-safe certification), print accuracy (Pantone color matching), and structural integrity (glue adhesion and dimensional accuracy).

For any brand selling a premium product like a gourmet cake, the packaging quality directly reflects the product quality. I’ve seen beautifully crafted desserts placed in poorly made boxes, and it instantly cheapens the entire experience. To prevent this, we work with our clients to establish a Quality KPI Scorecard right from the start. We agree on the exact paperboard—for example, 18pt C1S Food Grade SBS. We define the exact Pantone color codes for their branding. We even set standards for the glue, ensuring it’s odorless and food-safe. This isn’t about being difficult; it’s about being clear. When expectations are defined by measurable data instead of vague terms like "good," both the client and the supplier are protected. There is no room for error or misunderstanding.

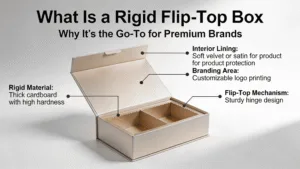

Material and Food Safety Compliance

This is a non-negotiable KPI for any food packaging.

- Paperboard Grade: Specify the exact type (e.g., SBS, Kraft, CCKB) and thickness (caliper, measured in points).

- Certifications: Ask for proof of certifications like FSC (Forest Stewardship Council) for sustainability or other food-grade safety compliance documents.

Print and Color Consistency

Your brand’s visual identity depends on this.

- Color Matching: Require proofs to be matched against a Pantone (PMS) number, not just a visual on a computer screen, for brand colors.

- Print Defects: Set an acceptable tolerance for issues like smudges, color variations, or misregistration.

Structural and Functional Integrity

The box must perform its primary function: protecting the product.

- Dimensional Accuracy: The final box must fold and assemble correctly. Provide a tolerance (e.g., +/- 1mm).

- Glue Adhesion: Seams and corners should not come apart. A simple manual stress test on samples can verify this.

| KPI Category | Key Metric | How to Measure |

|---|---|---|

| Material | Paperboard Grade & Caliper | Verify with spec sheet; measure sample with a caliper. |

| Food Safety | Food-Grade Certification1 | Request and verify certificates (e.g., FDA, SGS). |

| Printing | Pantone (PMS) Color Match2 | Compare final print to a physical Pantone swatch book. |

| Structural | Dimensional Accuracy | Assemble samples; measure with a ruler to ensure they match the die-line. |

| Structural | Glue Seam Strength | Manually pull at glued seams to test for separation. |

Conclusion

Choosing the right supplier for your dessert and cake boxes is a strategic business decision, not just a line item on a budget. By systematically evaluating potential partners on their MOQ, lead time reliability, and specific quality KPIs, you can build a resilient supply chain that supports your brand’s growth.

Find a partner who understands these details. Explore our custom paper box solutions or contact us directly to get a comprehensive quote tailored to your quality and logistical needs.

FAQ

What is a reasonable MOQ for a small bakery ordering custom boxes?

For small bakeries, a reasonable MOQ from a domestic or digitally-focused supplier is typically between 500 and 2,000 units. For high-volume offset printing from an overseas supplier, MOQs often start at 5,000 units or more to be cost-effective.

Should I choose a domestic or an overseas supplier?

Domestic suppliers generally offer lower MOQs and faster lead times, which is great for startups. Overseas suppliers, like Omet Packaging, often provide a significant cost advantage on larger orders but have longer lead times due to shipping.

How can I get a physical sample before placing a large order?

Most reputable suppliers offer sampling services. You can request a "stock sample" (a box they made for another client) to judge quality, or a "production-grade prototype" of your exact box. There may be a small fee for a custom prototype, which is often credited back on a full production order.

What’s the difference between a "digital proof" and a "physical sample"?

A digital proof is a PDF file showing how your artwork looks on the box die-line. It’s for checking layout and text. A physical sample is a fully made box you can hold and test, which is crucial for verifying colors, material, and structural integrity before mass production.